Services available for UHMW

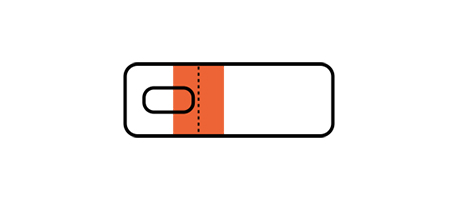

CNC routing excels at precisely cutting diverse materials, including composites, acrylics, and wood.

Learn More

Material Details

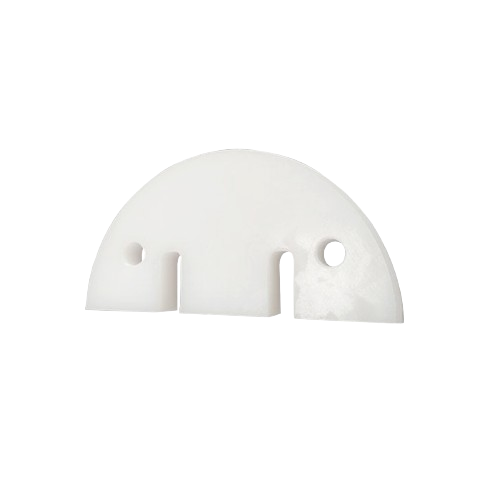

.354″ UHMW Plastic

- CNC Cutting View Specs

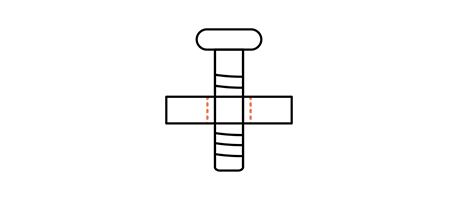

- Countersinking View Specs

| UHMW White .375" General Details | INCH | MM |

|---|---|---|

| Advertised Thickness | 0.375" | 9.525 mm |

| Gauge | N/A | N/A |

| Thickness tolerance positive | 0.038" | 0.965 mm |

| Thickness tolerance negative | 0.037" | 0.94 mm |

| Top/Bottom finish | Identical both sides | Identical both sides |

| Sourced from | USA | USA |

| CNC Router Cutting Specifications | INCH | MM |

| Cutting process | CNC Router | CNC Router |

| Cut tolerance +/- | 0.005" | 0.127 mm |

| Flatness tolerance before cutting | +/- 0.030 per foot | +/- 0.030 per foot |

| Min part size | 1.00″ x 2.00″ | 25.4 mm x 50.8 mm |

| Max part size | 44″ x 30″ | 1117.6 mm x 762 mm |

| Min hole size | 0.125″ | 3.175 mm |

| Min bridge size | 0.375″ | 9.525 mm |

| Min hole to edge distance | 0.113″ | 2.87 mm |

|

||

| Tab and slot tolerance | .045" | 1.143 mm |

|

||

| Countersink Specifications | INCH | MM |

| Min countersink part size | 1" x 4" | 25.4 mm x 101.6 mm |

| Max countersink part size | 14″ x 46″ | 355.6 mm x 1168.4 mm |

| Countersink Min Minor | 0.130" | 3.302 mm |

| Countersink Max Major | 0.656″ | 16.662 mm |

| Countersink Min Hole Center to Material Edge | 0.453" | 11.506 mm |

| UHMW Properties | INCH | MM |

| Material Composition | UHMW (Ultra-High-Molecular-Weight Polyethylene) is a thermoplastic polymer consisting of long chains of polyethylene with very high molecular weight. | UHMW (Ultra-High-Molecular-Weight Polyethylene) is a thermoplastic polymer consisting of long chains of polyethylene with very high molecular weight. |

| Density | 58.752 lb/ft3 | 58.752 lb/ft3 |

| Heat treatments process | N/A | N/A |

| ASTM | D4020 | D4020 |

| Tensile Strength (Ultimate) | 3.1 ksi | 3.1 ksi |

| Tensile Strength (Yield) | 2.8 ksi | 2.8 ksi |

| Shear Strength | 2.6 ksi | 2.6 ksi |

| Shear Modulus | 150 ksi | 150 ksi |

| Fatigue Strength | 2.2 ksi | 2.2 ksi |

| Hardness | Durometer 65D-67D | Durometer 65D-67D |

| Elongation at Break | 300% | 300% |

| Elastic Modulus | 100 ksi | 100 ksi |

| Poisson’s Ratio | 0.4 | 0.4 |

| Coefficient of Friction | 0.1-0.2 | 0.1-0.2 |

| Thermal Conductivity | 2.5 BTU/h-ft °F | 2.5 BTU/h-ft °F |

| Softening temperature | 176 °F | 176 °F |

| Magnetic | No | No |

| Does it Rust | No | No |

.500″ UHMW Plastic

- CNC Cutting View Specs

- Countersinking View Specs

| UHMW White .500" General Details | INCH | MM |

|---|---|---|

| Advertised Thickness | 0.500" | 12.7 mm |

| Gauge | N/A | N/A |

| Thickness tolerance positive | 0.050" | 1.27 mm |

| Thickness tolerance negative | 0.050" | 1.27 mm |

| Top/Bottom finish | Identical both sides | Identical both sides |

| Sourced from | USA | USA |

| CNC Router Cutting Specifications | INCH | MM |

| Cutting process | CNC Router | CNC Router |

| Cut tolerance +/- | 0.005" | 0.127 mm |

| Flatness tolerance before cutting | +/-0.030 per foot | +/-0.030 per foot |

| Min part size | 1.00″ x 2.000″ | 25.4 mm x 50.8 mm |

| Max part size | 44″ x 30″ | 1117.6 mm x 762 mm |

| Min hole size | .125″ | 3.175 mm |

| Min bridge size | .500″ | 12.7 mm |

| Min hole to edge distance | .150″ | 3.81 mm |

|

||

| Tab and slot tolerance | .055" | 1.397 mm |

|

||

| Countersink Specifications | INCH | MM |

| Min countersink part size | 1" x 4" | 25.4 mm x 101.6 mm |

| Max countersink part size | 14″ x 46″ | 355.6 mm x 1168.4 mm |

| Countersink Min Minor | .130" | 3.302 mm |

| Countersink Max Major | .656″ | 16.662 mm |

| Countersink Min Hole Center to Material Edge | .453" | 11.506 mm |

| UHMW Properties | INCH | MM |

| Material Composition | UHMW (Ultra-High-Molecular-Weight Polyethylene) is a thermoplastic polymer consisting of long chains of polyethylene with very high molecular weight. | UHMW (Ultra-High-Molecular-Weight Polyethylene) is a thermoplastic polymer consisting of long chains of polyethylene with very high molecular weight. |

| Density | 58.752 lb/ft^3 | 58.752 lb/ft^3 |

| Heat treatments process | N/A | N/A |

| ASTM | D4020 | D4020 |

| Tensile Strength (Ultimate) | 3.1 ksi | 3.1 ksi |

| Tensile Strength (Yield) | 2.8 ksi | 2.8 ksi |

| Shear Strength | 2.6 ksi | 2.6 ksi |

| Shear Modulus | 150 ksi | 150 ksi |

| Fatigue Strength | 2.2 ksi | 2.2 ksi |

| Hardness | Durometer 65D-67D | Durometer 65D-67D |

| Elongation at Break | 300% | 300% |

| Elastic Modulus | 100 ksi | 100 ksi |

| Poisson’s Ratio | 0.4 | 0.4 |

| Coefficient of Friction | 0.1-0.2 | 0.1-0.2 |

| Thermal Conductivity | 2.5 BTU/h-ft °F | 2.5 BTU/h-ft °F |

| Softening temperature | 176 °F | 176 °F |

| Magnetic | No | No |

| Does it Rust | No | No |

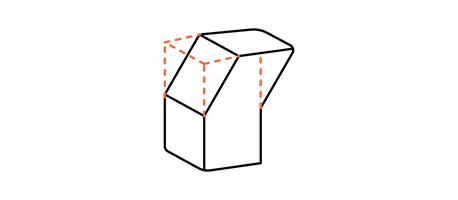

Additional Charts and Guidelines

Your estimated shipping date is dynamically calculated in your shopping cart as you add parts and services. Generally, production times for standard orders, excluding additional services such as bending or finishing, range from 2-4 business days prior to shipping.

The cut tolerance varies by material and is influenced by both the cutting processused and the material's thickness. For detailed tolerance information for each material,please visit our Materials Library. Select the material you are interested in, navigate to the Material Details section, choose your desired thickness, and review the specific tolerance data provided.

Discounts based on quantity are automatically calculated during the quoting process. As you add parts to your cart, you'll notice discounts of 20% or more when you order two or more identical parts in most materials. For even more substantial savings, consider signing up for our mailing list to receive notifications about exclusive, limited-time offers!

At our facility, we accept orders ranging from a single piece . With no minimum order requirement, you can request precisely the number of parts your project requires.

If you're unable to select a material for your part, it's often due to the part size being either too large or too small for the available materials. Please verify that your design file is set up at a 1:1 scale and is in either inches or millimeters. After uploading your file, also ensure that the correct unit of measurement is selected to match your design specifications.

Validate your login