USING THE BEND CALCULATOR

STEP 1:

Choose the material type, thickness, and desired units

STEP 2:

Input your base length

This represents the overall outside dimension of the base, center, or largest section of the part. For a U-channel, this would be the

outside dimension of the center section after bending.

STEP 3:

Input your flange dimensions.

Enter these dimensions as the desired outside dimensions after bending. You can adjust the flanges to be on either side of the base by selecting the left or right position.

Always measure formed flange lengths from the apex of the bend.

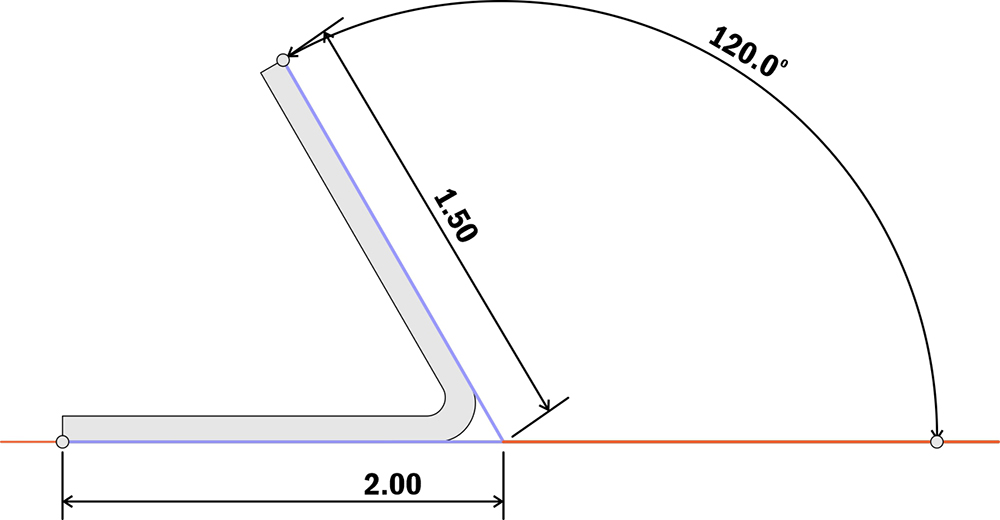

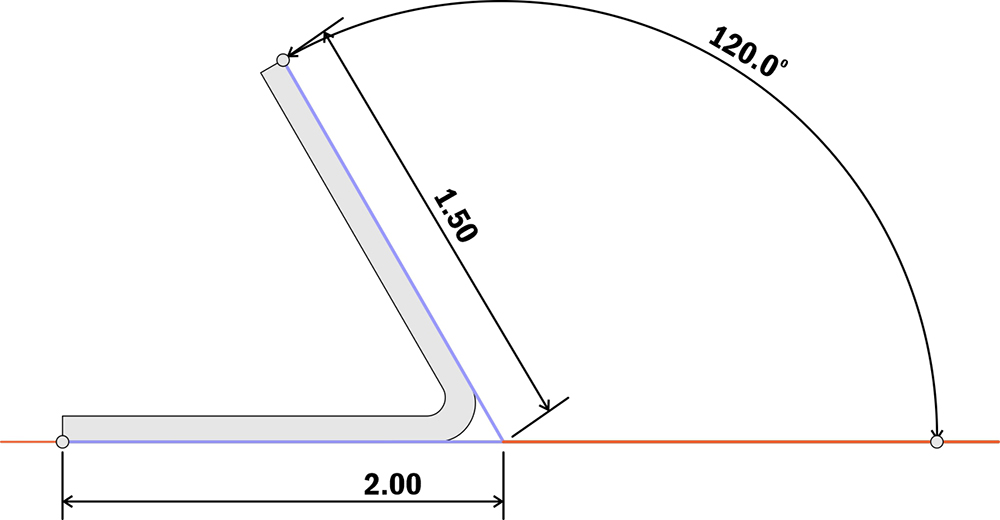

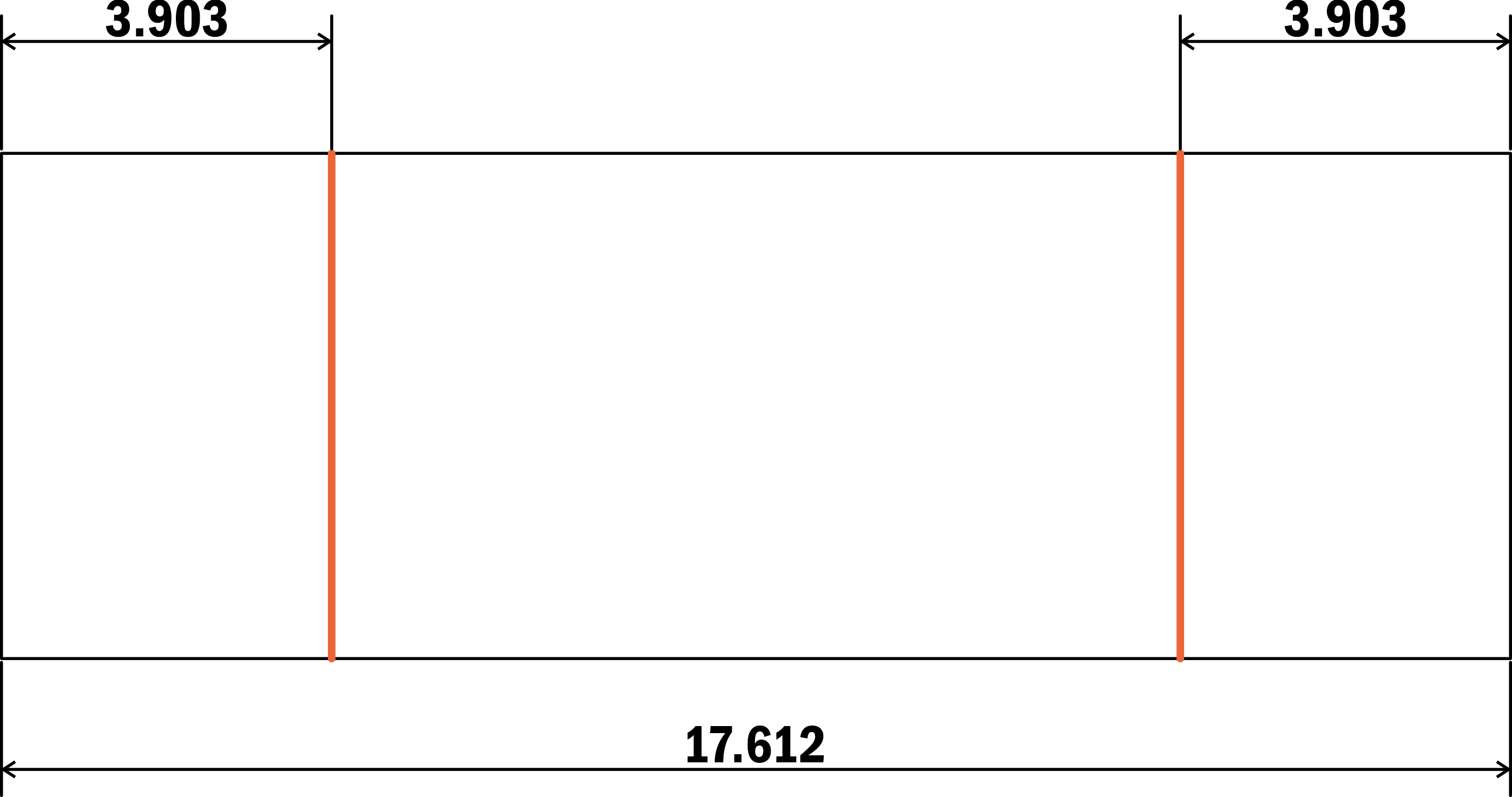

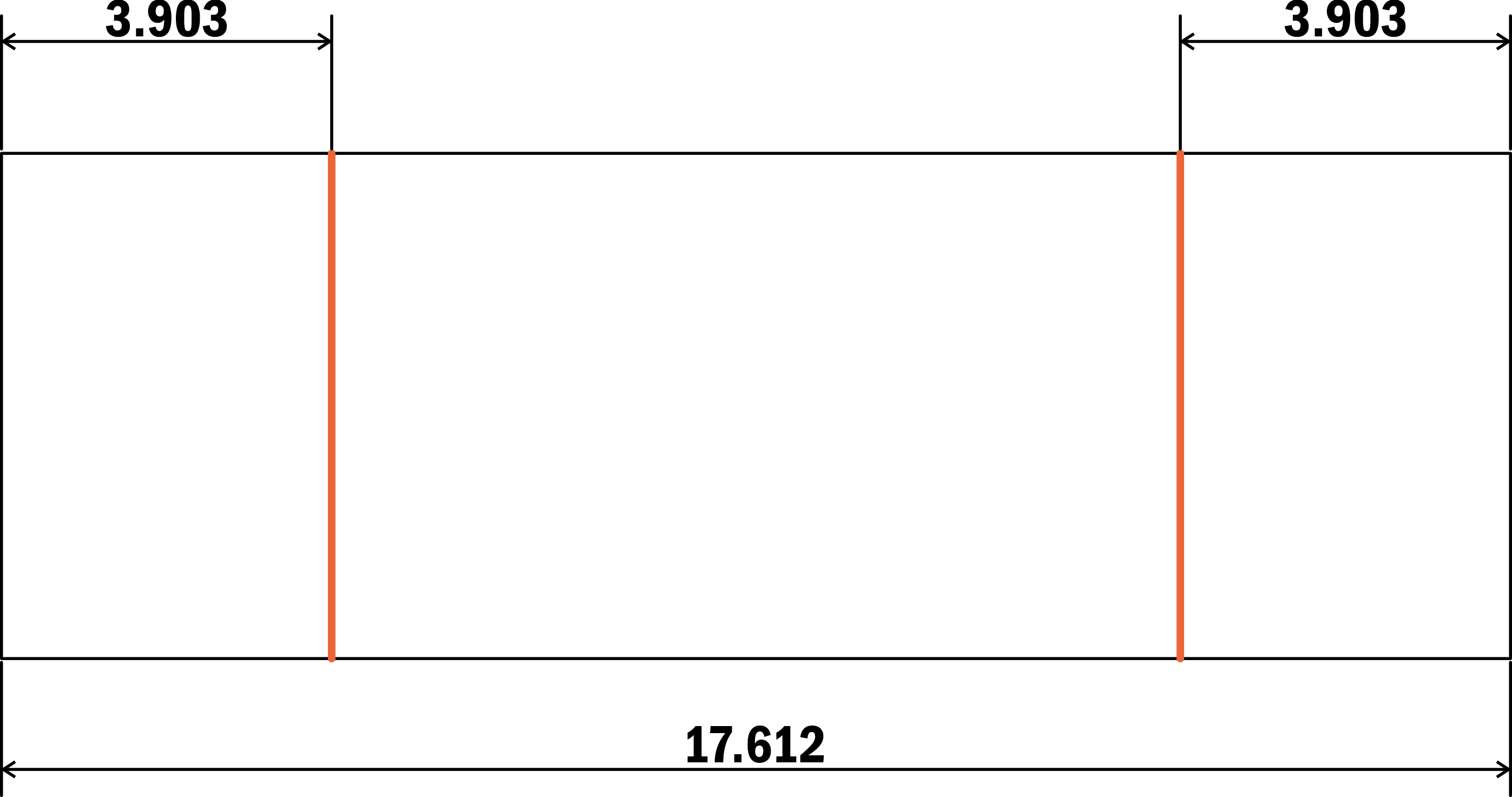

Example 1

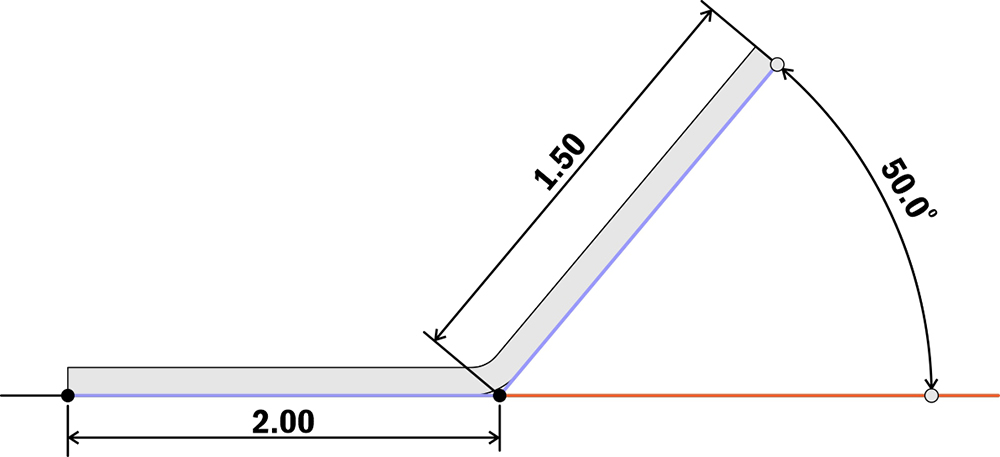

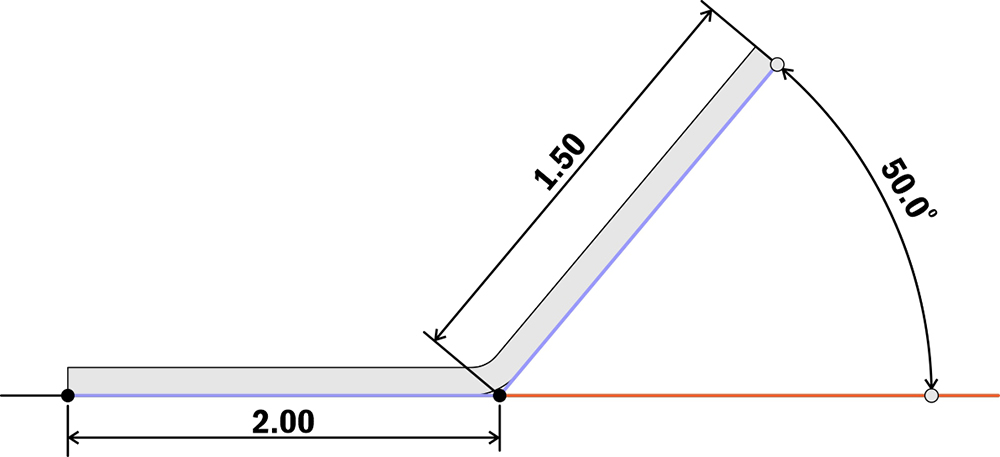

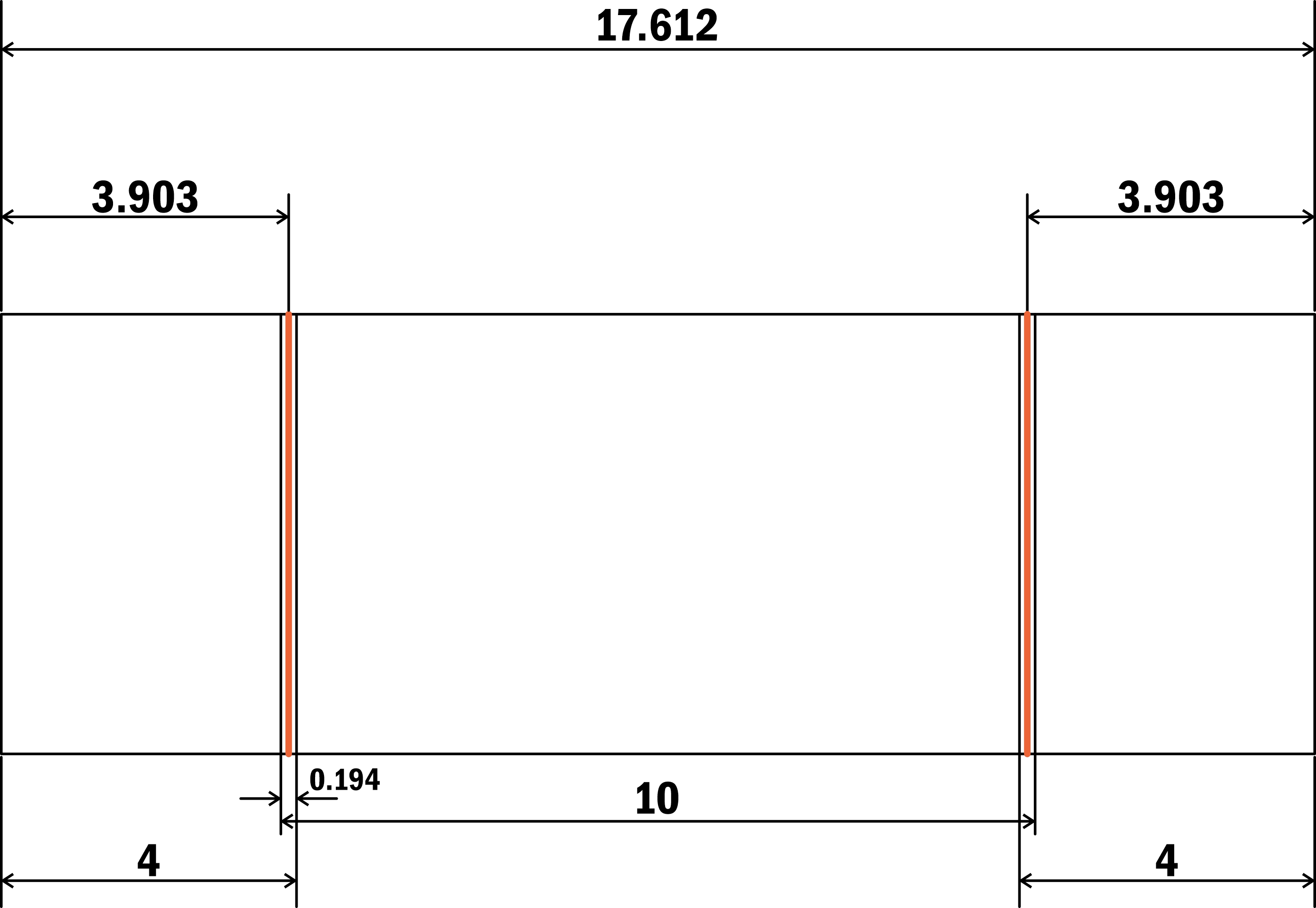

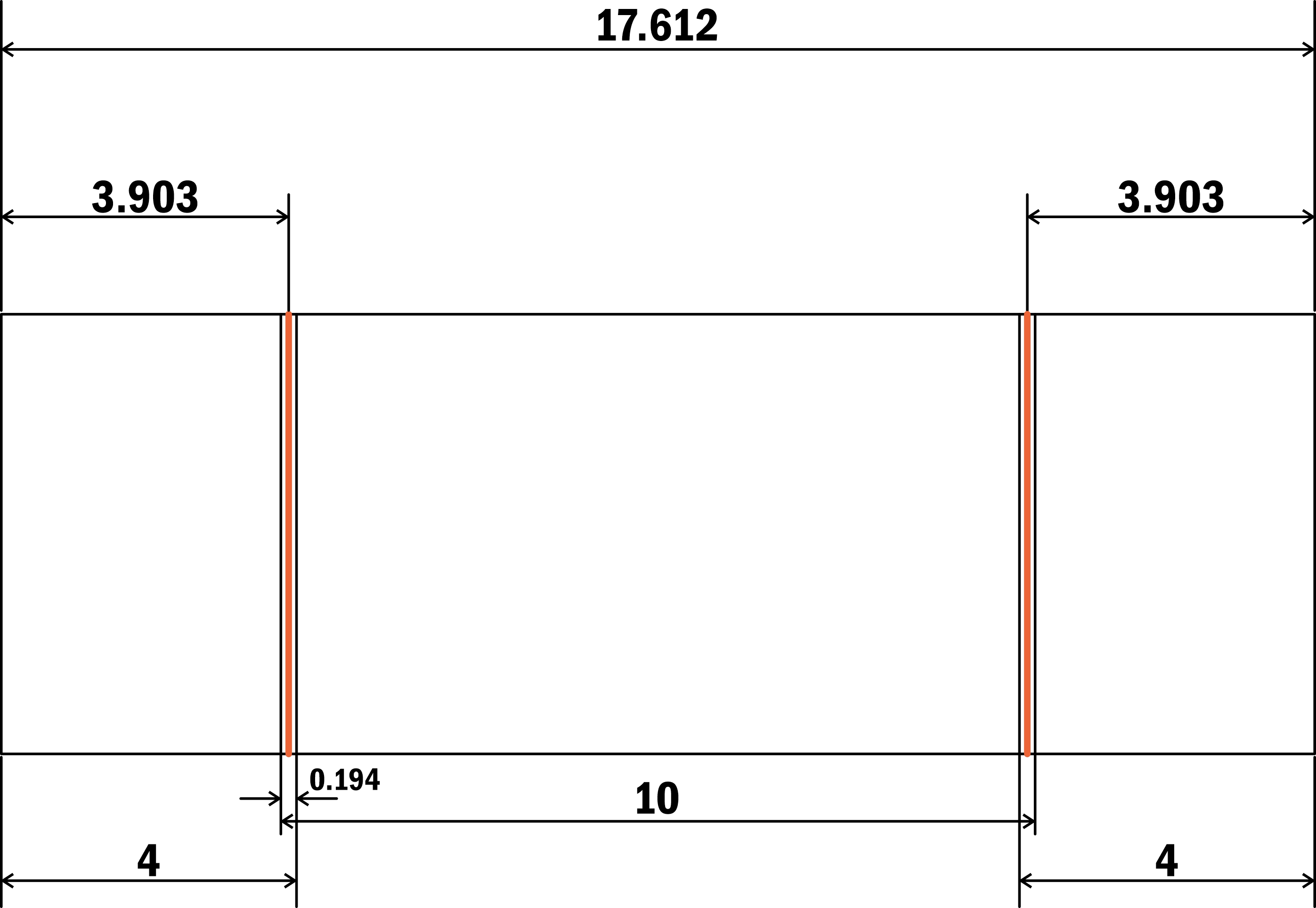

Example 2

This will generate a sketch view (see below) that shows where the bend lines need to be placed in the flat pattern, accounting for the bend deduction.

STEP 4:

Choose your view.

In the Results section, the default option is a flat view of the part for which you are gathering data.

You can choose the 3D view to verify that your bends are as expected.

STEP 5:

Modify your design

Next, modify your design to match the overall outside dimension (17.765”) and place the bend lines (3.903”) from the part's edge. After bending, it will achieve the desired outside flange dimensions (4” outside dimension) and base (10” outside dimension). See Example 1 below.

If you’re using 3D CAD software, draw the part with the flanges in place using the sheet metal function. Once you have the flanges set, edit the bend radius to match the advanced details provided at the bottom of the bending calculator. After updating the radius, adjust the K-factor or Bend Deduction value accordingly. To verify the part is correct, flatten it and measure the overall length and bend line locations against the bend calculator layout.

Remember, if you need a specific inside dimension, you should add some clearance (at least 0.030”) and adjust based on the material thickness. For example, this part will have an inside dimension of approximately 9.762”.

Example 1

Example 2

In this example, using 0.119” Mild Steel and bending at 90°, we have a bend deduction value of 0.194” for each bend, giving a total length of 17.612”.

The bend deduction value is listed in the “Advanced Details” section at the bottom of this page. To learn more about calculating bend deduction,

refer to our Guide to Calculating Bend Allowance and Bend Deduction. See Example 2 above.

Validate your login