Laser Cutting Design Density Guidelines

Guidelines and Tips for Reducing Design Density

AN OVERLY DENSE DESIGN CAN LEAD TO ADDITIONAL COSTS AND

SLOW DOWN PRODUCTION

Here are some of our top tips for keeping your parts affordable and faster to cut.

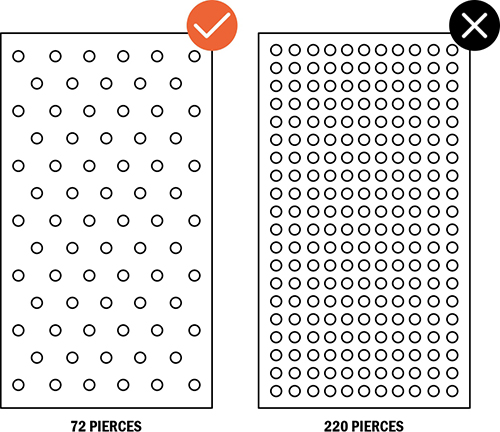

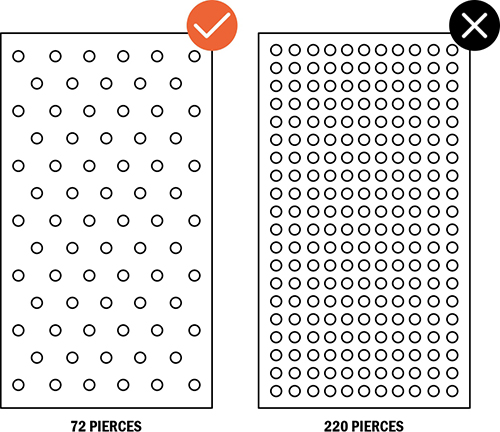

MINIMIZE THE NUMBER OF HOLES OR 'PIERCES'

Each time a hole or feature is created, the laser makes a pierce. The pierce can be the slowest part of the cutting process,

taking anywhere from 10 to 2,000 milliseconds depending on the material. Those milliseconds add up and can increase the

cost of your part

If you have a perforated pattern, try spacing the holes farther apart or increasing their size to reduce the total number of

holes in the design

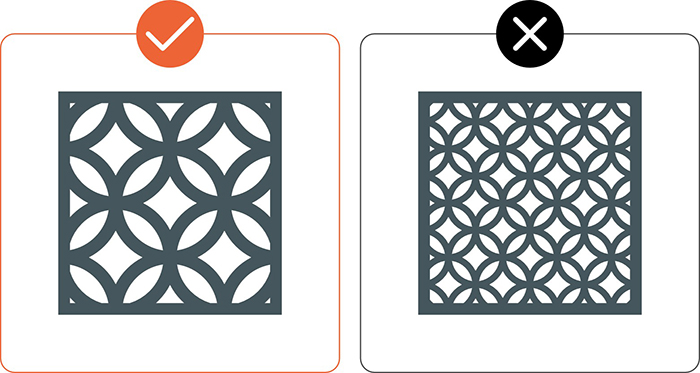

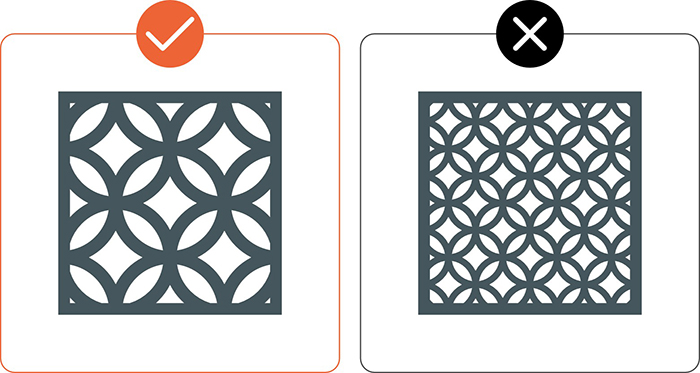

AVOID SUPER INTRICATE AND DELICATE PATTERNS

Our fiber laser is known for its accuracy and ability to cut small details, but there are still limitations.

Each cut takes time as the laser burns through the metal. Intricate designs with small bridges can

result in burnt edges and, at times, even warping.

In the example below, burn marks are visible on the edges of this intricate design. To address this,

we asked the customer to thicken the joining lines of the pattern.

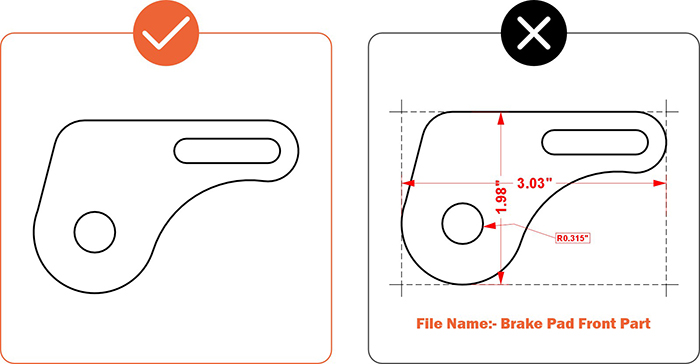

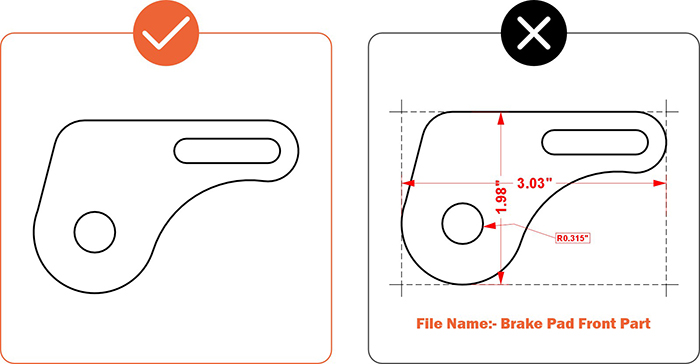

REMOVE DUPLICATE LINES AND UNNECESSARY GEOMETRY.

When designing using layers, guides, construction lines, rulers, etc., unnecessary design artifacts can appear in your

exported DXF file. We recommend opening your DXF file and running a few checks:

- Delete all unused layers.

- Remove hidden or locked objects.

- Remove guides and construction lines.

- Delete text notes and dimensions.

- Remove borders, titles, and part numbers.

Basically, the only geometry we need is the cutting path for the laser to follow.

For more details, check out our Design Guidelines.

Pre-flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- Ensure all holes and cutouts are at least 50% of the material thickness for laser cut parts

- Ensure all holes and cutouts are at least 0.070” for most waterjet cut parts

- For all CNC routed parts, holes and cutouts must be at least 0.125”

- Create your file at a 1:1 scale, preferably using inch or millimeter units

- Ensure all objects are placed on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure no shapes have open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) includes bridges or is stencilized

Validate your login