GENERAL SIZE REQUIREMENTS

If you’re looking for instant pricing using our online quote tool, keep in mind that even nested files need to fit within our sizing requirements. The maximum overall part size for instant quoting will vary depending on the material you use. Check your file and chosen material against the Material Max/Min chart to ensure you can get instant pricing.

Top of Form

If your file exceeds the size limit for your chosen material, we recommend splitting each part into individual files to receive instant pricing. If your parts are still too large, you can always request a custom quote.

It's important to ensure that your individual nested parts meet the minimum geometry requirements for the material and machining method. Geometry that’s too small cannot be cut accurately and will yield undesirable results. Check your parts against our design guidelines before uploading to make sure they meet the necessary requirements.

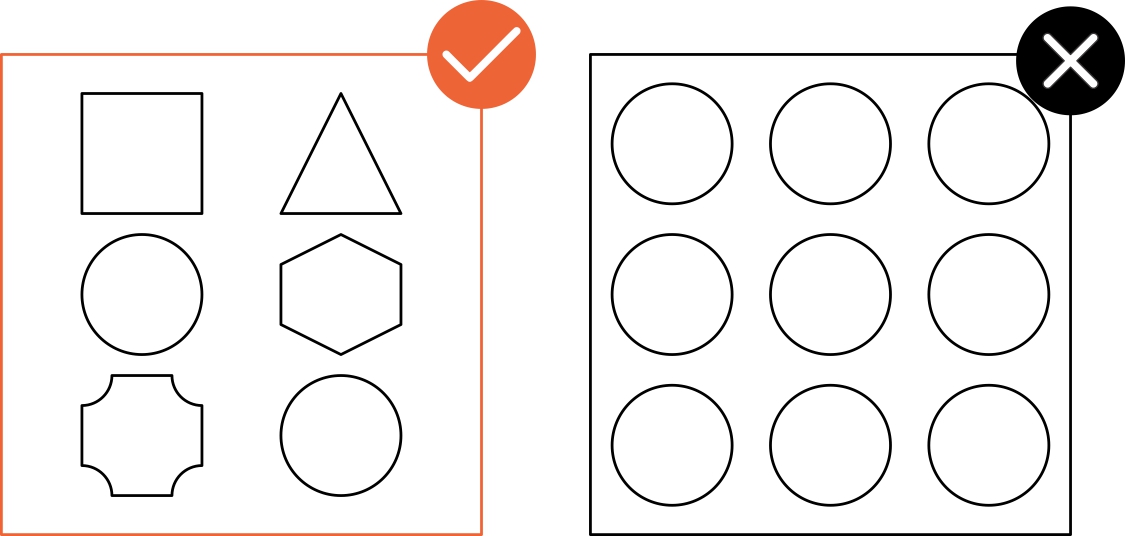

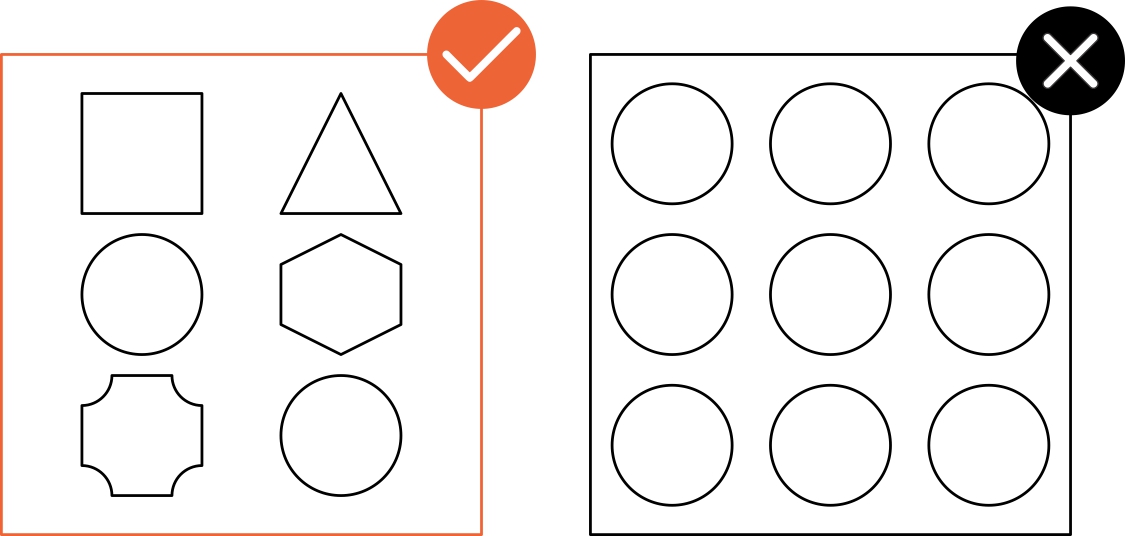

NESTING UNIQUE, INDIVIDUAL DESIGNS

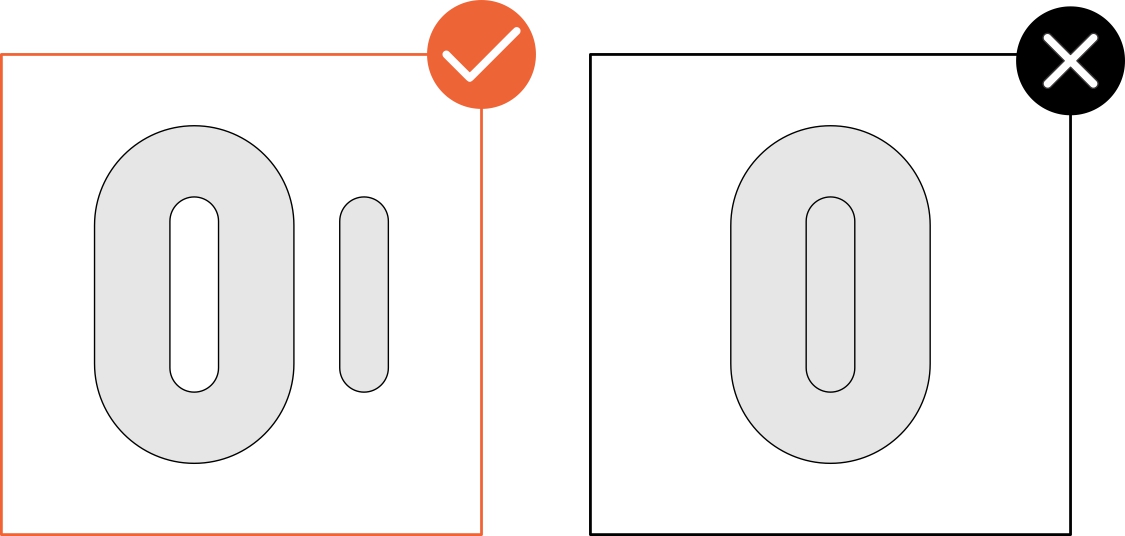

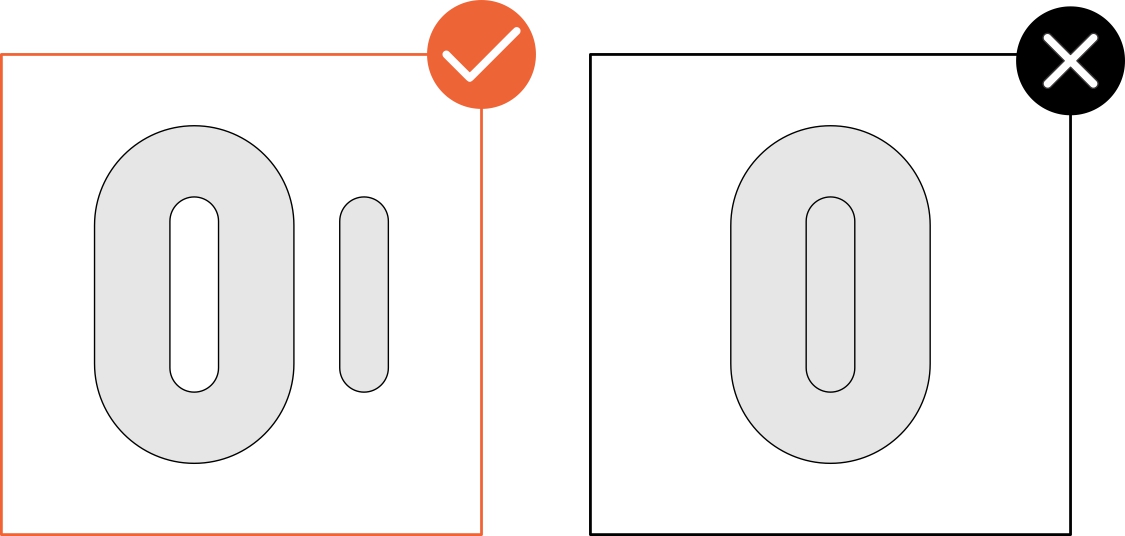

To order multiple quantities of the exact same part, include only one part per file (no nesting) and adjust the quantity in your cart during checkout.

This simplifies processing once we receive your order, ensuring your parts are cut efficiently.

You will also receive a quantity discount on multiples of the same part.

If you are ordering several different small parts or designs, you can pre-nest those parts and upload them in one file, as long as all geometry meets our sizing requirements. To save time, you can also upload each part in its own file instead.

PARTS WITH ADDITIONAL PROCESSES

Please do not pre-nest parts that require bending, tapping, countersinking,

or hardware. Submitting these parts separately ensures your order moves

smoothly through production.

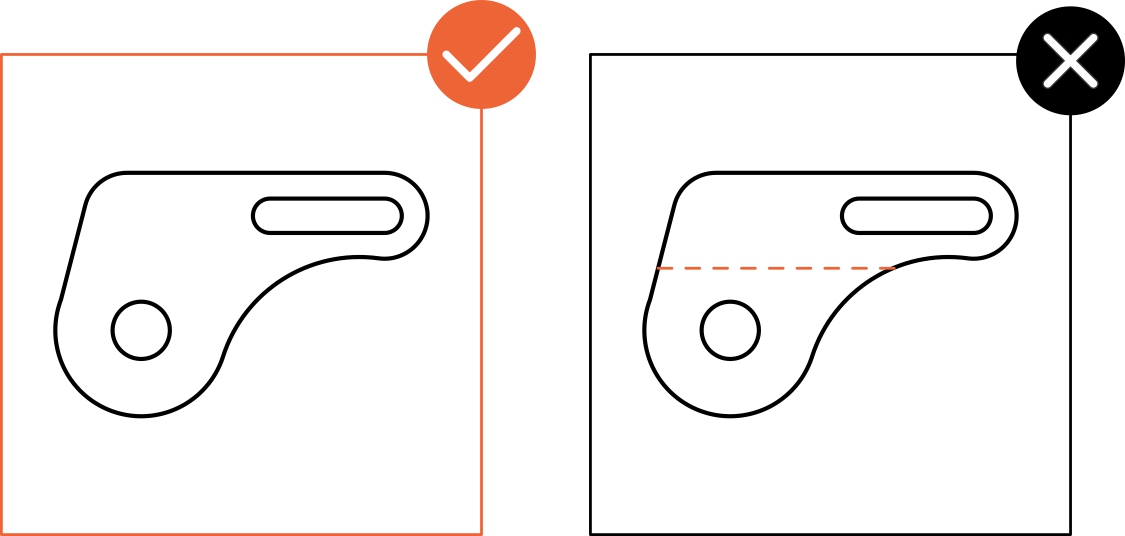

COMMON-LINE NESTING

Common-line nesting involves nesting parts inside each other and having them share a cut path to ensure a precision fit or save material.

We do not accept or process common-line nested parts because it can lead to imprecise parts.

This method doesn't account for the laser cutter beam width, tooling size, waterjet stream width, or kerf.

Depending on the material and machining process, the gap between the parts will vary from 0.006″ to 0.012″ or more. Design the inner part about 0.005″ smaller to allow for a slip-fit, and place the inner part in a separate file or elsewhere in the original file so that none of the lines between the parts are shared. For more guidance on designing a slip-fit for mating parts, refer to our detailed instructions here.

Parts with common-line nesting will also have manufacturing imperfections, such as pierces and "lead-in" marks used to start the cut.

Due to these issues, files with common-line nesting will be returned for revision, delaying the lead time of your order.

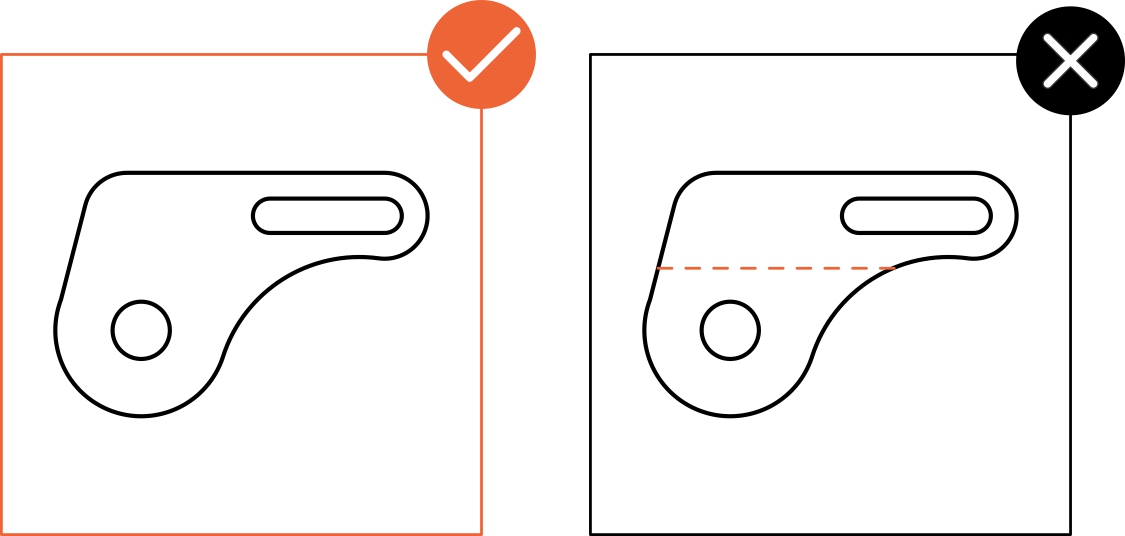

PARTS WITHIN PARTS

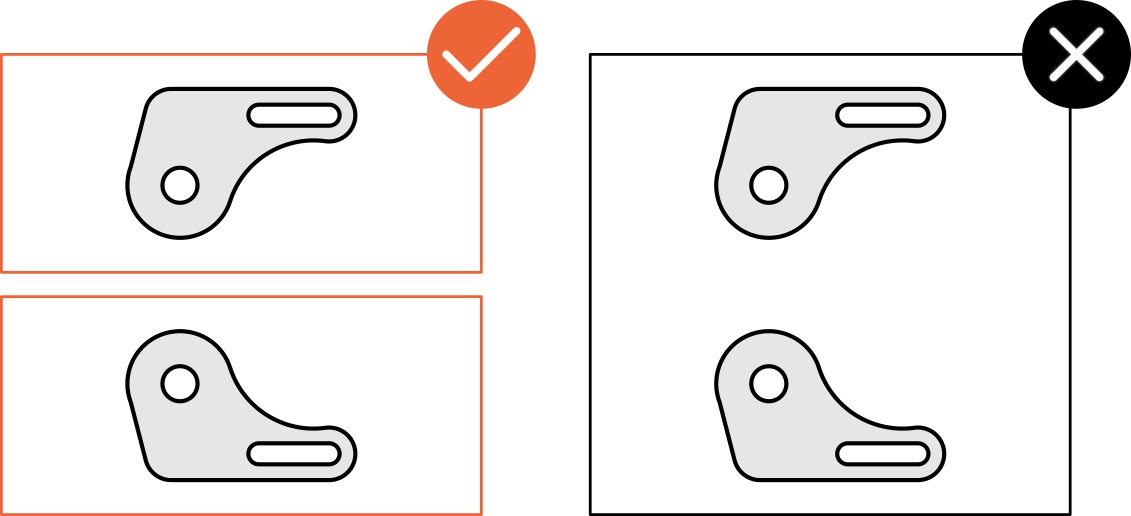

If you decide to pre-nest unique, individual designs, avoid sending files with parts nested within each other (parts inside parts). Instead, keep each part separated within your file. This will ensure the fastest turnaround time for your order. Otherwise, we will have to put your order on hold and request a new file.

PART ORIENTATION CONSIDERATIONS

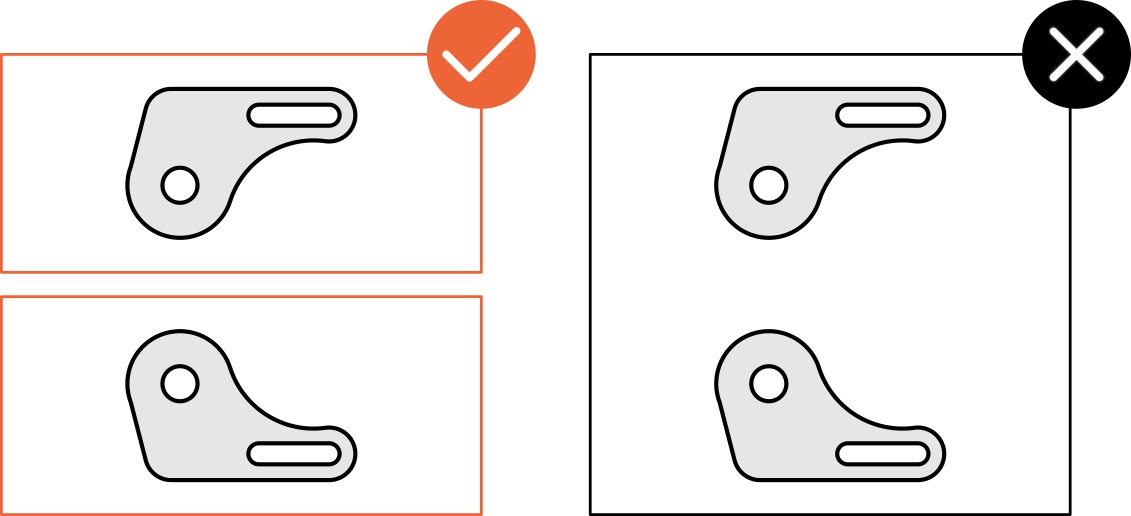

If you save multiple identical parts into the same file, we cannot guarantee which side of the parts will be the top side.

This is particularly important if mirrored parts are desired in materials with distinct top and

bottom sides (such as ABS, brushed ACM, mirrored acrylic, and hardboard).

If your application requires mirrored parts with a specific top and bottom side, save each mirrored part in its own file and adjust the quantity as needed before checkout. The orientation shown in the item preview will determine the top side of the parts.

Pre-Flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- All holes and cutouts are at least 50% of the material's thickness for laser cut parts

- All holes and cutouts are at least 0.070” for most waterjet cut parts

- All holes and cutouts are at least 0.125” for all CNC routed parts

- Ensure the file is created at a 1:1 scale, preferably in inch or millimeter units

- Ensure all objects are on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure all shapes are fully enclosed with no open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) has bridges or has been stencilized

Validate your login