Services available for G90 Galvanized Steel

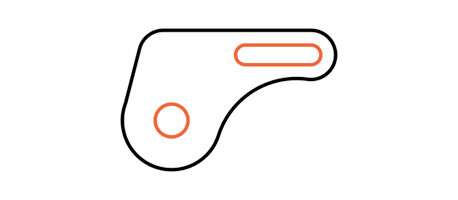

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

Learn More

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors.

Learn More

Quickly and easily add threading to allow for the addition of hardware to your parts.

Learn MoreMaterial Details

.036″ G90 Steel

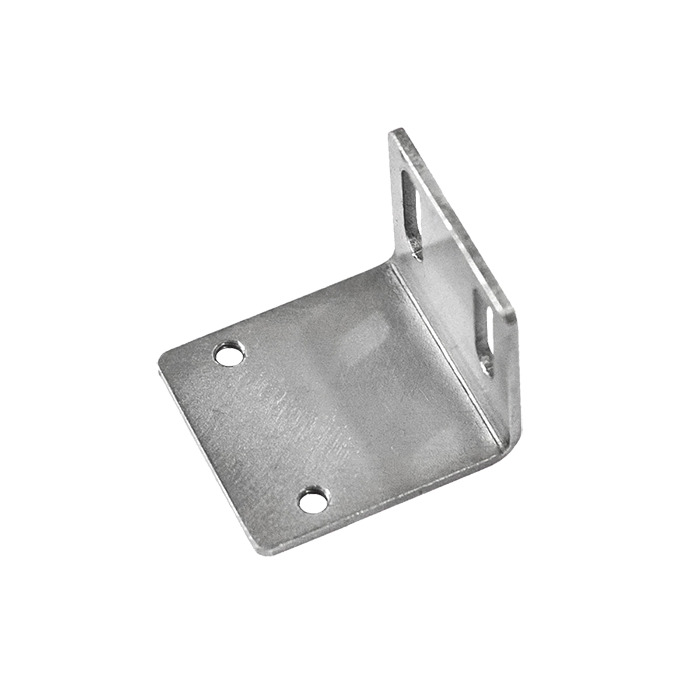

- Laser Cutting View Specs

- Bending View Specs

- Powder Coating View Specs

| G90 .036" General Details | INCH | MM |

|---|---|---|

| Advertised Thickness | 0.036" | 0.914 mm |

| Gauge | 20 | 20 |

| Thickness tolerance positive | 0.005" | 0.127 mm |

| Thickness tolerance negative | 0.005" | 0.127 mm |

| Mill finish | Cold rolled, hot dipped galvanized | Cold rolled, hot dipped galvanized |

| Sourced from | USA | USA |

| Laser Cutting Specifications | INCH | MM |

| Cutting process | Fiber laser | Fiber laser |

| Cut tolerance +/- | 0.005" | 0.127 mm |

| Flatness tolerance before cutting | +/-0.030 per foot | +/-0.030 per foot |

| Min part size | .25″ x .375″ | 6.35 mm x 9.525 mm |

| Min hole size | 0.020" | 0.508 mm |

| Min bridge size | 0.020" | 0.508 mm |

| Min bridge size | .063″ | 1.6 mm |

| Min hole to edge size | 0.020" | 0.508 mm |

|

||

| Tab and slot tolerance | .010" | 0.254 mm |

|

||

| Bending Specifications | INCH | MM |

| Min Bend Part Size | .375" x 1.5" | 9.525 mm x 38.1 mm |

| Max Bending Flat Part Size | 44" x 30" | 1117.6 mm x 762 mm |

| Max Bend Length | 44" | 1117.6 mm |

| Min Flange Length (Before Bend/Flat Pattern) 90° or less (obtuse) | 0.255" | 6.477 mm |

| Min Flange Length (After Bend) 90° or less (obtuse) | 0.298" | 7.569 mm |

| Minimum Length Center of bend line 91-130* (Acute) | 0.344" | 8.738 mm |

| Die Width | 0.472" | 11.989 mm |

| Effective Bend Radius @ 90° | 0.045" | 1.143 mm |

| Max Bend Angle | 130° | 130° |

| Bend angle tolerance (bend length up to 24″) | +/- 1 degree | +/- 1 degree |

| Bend angle tolerance (bend length over 24″) | +/- 2 degrees | +/- 2 degrees |

| Bend Deduction @ 90° | 0.073" | 1.854 mm |

| K Factor | 0.38 | 0.38 |

| Bend Relief Depth | 0.101" | 2.565 mm |

| Minimum Joggle. Bend Line to Bend Line @90° Max Flange | 0.295" | 7.493 mm |

| Maximum Joggle. Bend Line to Bend Line @90° Max Flange | 3.750" | 95.25 mm |

| Powder Coating Specifications | INCH | MM |

| Min Powder Coating Part Size | 1" x 3" | 25.4 mm x 76.2 mm |

| Max Powder Coating Part Size | 23" x 23" | 584.2 mm x 584.2 mm |

| G90 Properties | INCH | MM |

| Material Composition | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 |

| Density | 490 lb/ft^3 | 490 lb/ft^3 |

| Heat treatments process | N/A | N/A |

| ASTM | ASTM A653 G90 CS TYPE A | ASTM A653 G90 CS TYPE A |

| Tensile Strength (Ultimate) | 58-65 ksi | 58-65 ksi |

| Tensile Strength (Yield) | 46 ksi | 46 ksi |

| Shear Strength | 34 ksi | 34 ksi |

| Shear Modulus | 11.5 ksi | 11.5 ksi |

| Fatigue Strength | 32 ksi | 32 ksi |

| Brinell Hardness | 120-180 | 120-180 |

| Elongation at Break | 20% | 20% |

| Elastic Modulus | 29000 ksi | 29000 ksi |

| Poisson’s Ratio | 0.3 | 0.3 |

| Thermal Conductivity | 8 BTU/h-ft °F | 8 BTU/h-ft °F |

| Melting Point | 2500-2800 °F | 2500-2800 °F |

| Magnetic | Yes | Yes |

| Does it Rust | Yes | Yes |

.048″ G90 Steel

- Laser Cutting View Specs

- Bending View Specs

- Hardware View Specs

- Powder Coating View Specs

| G90 .048" General Details | INCH | MM |

|---|---|---|

| Advertised Thickness | 0.048" | 1.219 mm |

| Gauge | 18 | 18 |

| Thickness tolerance positive | 0.005" | 0.127 mm |

| Thickness tolerance negative | 0.005" | 0.127 mm |

| Mill Finish | Cold rolled, hot dipped galvanized | Cold rolled, hot dipped galvanized |

| Top/Bottom Finish | Identical both sides | Identical both sides |

| Sourced from | USA | USA |

| Laser Cutting Specifications | INCH | MM |

| Cutting process | Fiber laser | Fiber laser |

| Cut tolerance +/- | 0.005" | 0.127 mm |

| Flatness tolerance before cutting | +/-0.030 per foot | +/-0.030 per foot |

| Min part size | 0.25" x 0.375" | 6.35 mm x 9.525 mm |

| Min hole size | 0.018" | 0.457 mm |

| Min bridge size | 0.024" | 0.61 mm |

| Min hole to edge size | 0.020" | 0.508 mm |

|

||

| Tab and slot tolerance | .010" | 0.254 mm |

|

||

| Bending Specifications | INCH | MM |

| Min Bend Part Size | 0.375" x 1.5" | 9.525 mm x 38.1 mm |

| Max Bending Flat Part Size | 44" x 30" | 1117.6 mm x 762 mm |

| Max Bend Length | 44" | 1117.6 mm |

| Min Flange Length (Before Bend/Flat Pattern) 90° or less (obtuse) | 0.255" | 6.477 mm |

| Min Flange Length (After Bend) 90° or less (obtuse) | 0.298" | 7.569 mm |

| Minimum Length Center of bend line 91-130° (Acute) | 0.344" | 8.738 mm |

| Die Width | 0.472" | 11.989 mm |

| Effective Bend Radius @ 90° | 0.045" | 1.143 mm |

| Max Bend Angle | 130° | 130° |

| Bend angle tolerance (bend length up to 24″) | +/- 1 degree | +/- 1 degree |

| Bend angle tolerance (bend length over 24″) | +/- 2 degrees | +/- 2 degrees |

| Bend Deduction @ 90° | 0.086" | 2.184 mm |

| K Factor | 0.38 | 0.38 |

| Bend Relief Depth | 0.113" | 2.87 mm |

| Minimum Joggle. Bend Line to Bend Line @90° Max Flange | 0.308" | 7.823 mm |

| Maximum Joggle. Bend Line to Bend Line @90° Max Flange | 3.750" | 95.25 mm |

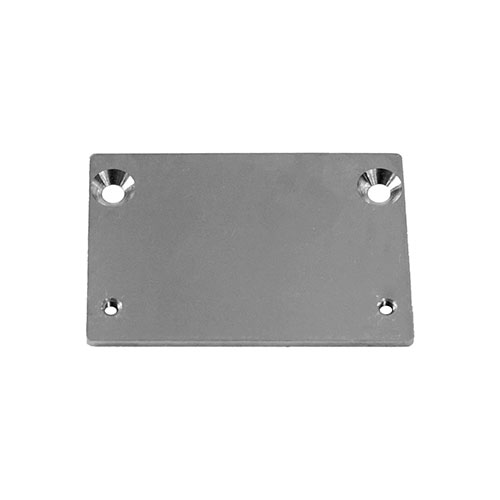

| Hardware Specifications | INCH | MM |

| Hardware Min Part Size | 1" x 1.5" | 25.4 mm x 38.1 mm |

| Hardware Max Part Size | 36" x 46" | 914.4 mm x 1168.4 mm |

| Minimum distance from center of bend to center of hardware insertion hole (measured from flat pattern) | 0.425" | 10.795 mm |

| Max 4 sided box flange height (hardware) | 3" | 76.2 mm |

| Hardware specific specifications | Please view our Hardware Catalog | Please view our Hardware Catalog |

| Powder Coating Specifications | INCH | MM |

| Min powder coating part size | 1" x 3" | 25.4 mm x 76.2 mm |

| Max powder coating part size | 23" x 23" | 584.2 mm x 584.2 mm |

| G90 Properties | INCH | MM |

| Material Composition | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 |

| Density | 490 lb/ft^3 | 490 lb/ft^3 |

| Heat treatments process | N/A | N/A |

| ASTM | ASTM A653 G90 CS TYPE A | ASTM A653 G90 CS TYPE A |

| Tensile Strength (Ultimate) | 58-65 ksi | 58-65 ksi |

| Tensile Strength (Yield) | 46 ksi | 46 ksi |

| Shear Strength | 34 ksi | 34 ksi |

| Shear Modulus | 11.5 ksi | 11.5 ksi |

| Fatigue Strength | 32 ksi | 32 ksi |

| Brinell Hardness | 120-180 | 120-180 |

| Elongation at Break | 20% | 20% |

| Elastic Modulus | 29000 ksi | 29000 ksi |

| Poisson’s Ratio | 0.3 | 0.3 |

| Thermal Conductivity | 8 BTU/h-ft °F | 8 BTU/h-ft °F |

| Melting Point | 2500-2800°F | 2500-2800°F |

| Magnetic | Yes | Yes |

| Does it Rust | Yes | Yes |

.059″ G90 Steel

- Laser Cutting View Specs

- Bending View Specs

- Hardware View Specs

- Powder Coating View Specs

- Tapping View Specs

| G90 .059" General Details | INCH | MM |

|---|---|---|

| Advertised Thickness | 0.059" | 1.4986 mm |

| Gauge | 16 | 16 |

| Thickness tolerance positive | 0.006" | 0.1524 mm |

| Thickness tolerance negative | 0.004" | 0.1016 mm |

| Mill finish | Cold rolled, hot dipped galvanized | Cold rolled, hot dipped galvanized |

| Top/Bottom Finish | Identical both sides | Identical both sides |

| Sourced from | USA | USA |

| Laser Cutting Specifications | INCH | MM |

| Cutting process | Fiber laser | Fiber laser |

| Cut tolerance +/- | 0.005" | 0.127 mm |

| Flatness tolerance before cutting | +/-0.030 per foot | +/-0.030 per foot |

| Min part size | .25" x .375" | 635 X 9525 mm |

| Min hole size | 0.022" | 0.5588 mm |

| Min bridge size | 0.030" | 0.762 mm |

| Min hole to edge size | 0.020" | 0.508 mm |

|

||

| Tab and slot tolerance | 0.010" | 0.254 mm |

|

||

| Bending Specifications | INCH | MM |

| Min Bend Part Size | .375" x 1.5" | 9.525 X 38.1 mm |

| Max Bending Flat Part Size | 44" x 30" | 1117.6 X 762 mm |

| Max Bend Length | 44" | 1117.6 mm |

| Min Flange Length (Before Bend/Flat Pattern) 90° or less (obtuse) | 0.255" | 6.477 mm |

| Min Flange Length (After Bend) 90° or less (obtuse) | 0.311" | 7.8994 mm |

| Minimum Length Center of bend line 91-130* (Acute) | .344" | 8.7376 mm |

| Die Width | 0.472" | 11.9888 mm |

| Effective Bend Radius @ 90° | 0.063" | 1.6002 mm |

| Max Bend Angle | 130° | 130° |

| Bend angle tolerance (bend length up to 24″) | +/- 1 degree | +/- 1 degree |

| Bend angle tolerance (bend length over 24″) | +/- 2 degrees | +/- 2 degrees |

| Bend Deduction @ 90° | 0.112" | 2.8448 mm |

| K Factor | 0.36 | 9.144 mm |

| Bend Relief Depth | 0.142" | 3.6068 mm |

| Minimum Joggle. Bend Line to Bend Line @90° Max Flange | 0.320" | 8.128 mm |

| Maximum Joggle. Bend Line to Bend Line @90° Max Flange | 3.750" | 95.25 mm |

| Hardware Specifications | INCH | MM |

| Hardware Min Part Size | 1" x 1.5" | 25.4 X 38.1 mm |

| Hardware Max Part Size | 36" x 46" | 914.4 X 1168.4 mm |

| Minimum distance from center of bend to center of hardware insertion hole (measured from flat pattern) | 0.441" | 11.2014 mm |

| Max 4 sided box flange height (hardware) | 3" | 76.2 mm |

| Hardware specific specifications | Please view our Hardware Catalog | Please view our Hardware Catalog |

| Powder Coating Specifications | INCH | MM |

| Min powder coating part size | 1" x 3" | 25.4 X 76.2 mm |

| Max powder coating part size | 23" x 23" | 584.2 X 584.2 mm |

| Tapping Specifications | INCH | MM |

| Largest Tap | M3 x 0.5 | M3 x 0.5 |

| Smallest Tap | M2 x 0.4 | M2 x 0.4 |

| Min Flat Part Size Tapping | 0.949" x 1.5" | 24.1046 X 38.1 mm |

| Max Flat Part Size Tapping | 36" x 46" | 914.4 X 1168.4 mm |

| Tapping Min Hole to Edge | 0.030" | 0.762 mm |

| Tapping Min Hole Center to Material Edge | Tap hole size/2 +0.030" | Tap hole size/2 +0.030" |

| G90 Properties | INCH | MM |

| Material Composition | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 | Carbon/0.03, Manganese/0.17, Phosphorus/0.011, Sulfur/0.002, Silicon/0.03, Copper/0.12, Tin/0.006, Nickel/0.04, Chromium/0.05, Molybdenum/0.01, Aluminum/0.043, Nitrogen/0.0063, Vanadium/<0.001, Niobium/<0.001, Titanium/0.001, Boron/<0.0001, Calcium/0.0016 |

| Density | 490 lb/ft³ | 490 lb/ft³ |

| Heat treatments process | N/A | N/A |

| ASTM | ASTM A653 G90 CS TYPE A | ASTM A653 G90 CS TYPE A |

| Tensile Strength (Ultimate) | 58-65 ksi | 58-65 ksi |

| Tensile Strength (Yield) | 46 ksi | 46 ksi |

| Shear Strength | 34 ksi | 34 ksi |

| Shear Modulus | 11000 ksi | 11000 ksi |

| Fatigue Strength | 32 ksi | 32 ksi |

| Brinell Hardness | 120-180 | 120-180 |

| Elongation at Break | 20% | 20% |

| Elastic Modulus | 29000 ksi | 29000 ksi |

| Poisson’s Ratio | 0.3 | 0.3 |

| Thermal Conductivity | 36 BTU/h-ft °F | 36 BTU/h-ft °F |

| Melting Point | 2500-2800 °F | 2500-2800 °F |

| Magnetic | Yes | Yes |

| Does it Rust | Yes | Yes |

Additional Charts and Guidelines

Your estimated shipping date is dynamically calculated in your shopping cart as you add parts and services. Generally, production times for standard orders, excluding additional services such as bending or finishing, range from 2-4 business days prior to shipping.

The cut tolerance varies by material and is influenced by both the cutting processused and the material's thickness. For detailed tolerance information for each material,please visit our Materials Library. Select the material you are interested in, navigate to the Material Details section, choose your desired thickness, and review the specific tolerance data provided.

Discounts based on quantity are automatically calculated during the quoting process. As you add parts to your cart, you'll notice discounts of 20% or more when you order two or more identical parts in most materials. For even more substantial savings, consider signing up for our mailing list to receive notifications about exclusive, limited-time offers!

At our facility, we accept orders ranging from a single piece . With no minimum order requirement, you can request precisely the number of parts your project requires.

If you're unable to select a material for your part, it's often due to the part size being either too large or too small for the available materials. Please verify that your design file is set up at a 1:1 scale and is in either inches or millimeters. After uploading your file, also ensure that the correct unit of measurement is selected to match your design specifications.

Validate your login