ORDER REQUIREMENTS

For the fastest turnaround time, we recommend placing your powder-coated parts in a separate order from your non-powder coated parts. This approach ensures the best possible lead time for all your parts.

We continue to cut and ship your orders at our usual break-neck speed. However, please keep in mind that powder coating will add 7-10 days to the production time. We believe the final look of your parts will be worth the wait!

OENHANCED DURABILITY AVAILABLE IN A VARIETY OF COLORS.

Black Glossy

Black Matt

Wrinkle Black

Glossy White

Glossy Green

Glossy Red

Glossy Yellow

GEOMETRY REQUIREMENTS FOR POWDER COATING

SUMMARY:

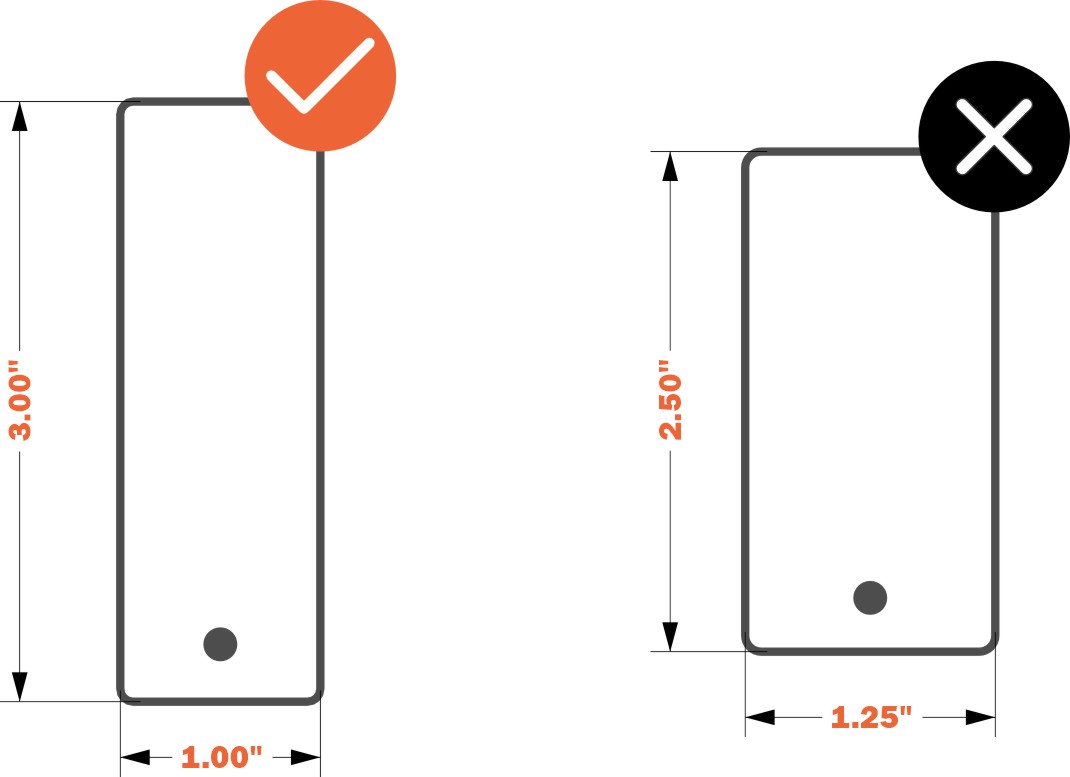

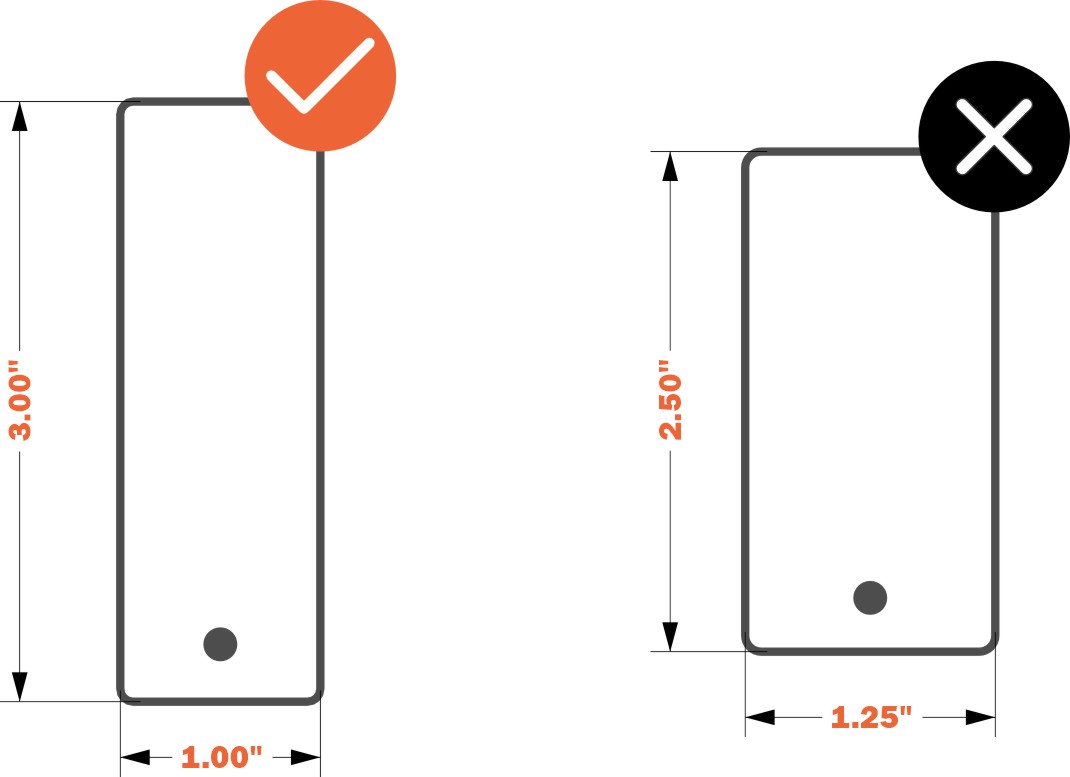

- Minimum part size: 3"; maximum part size: 23"

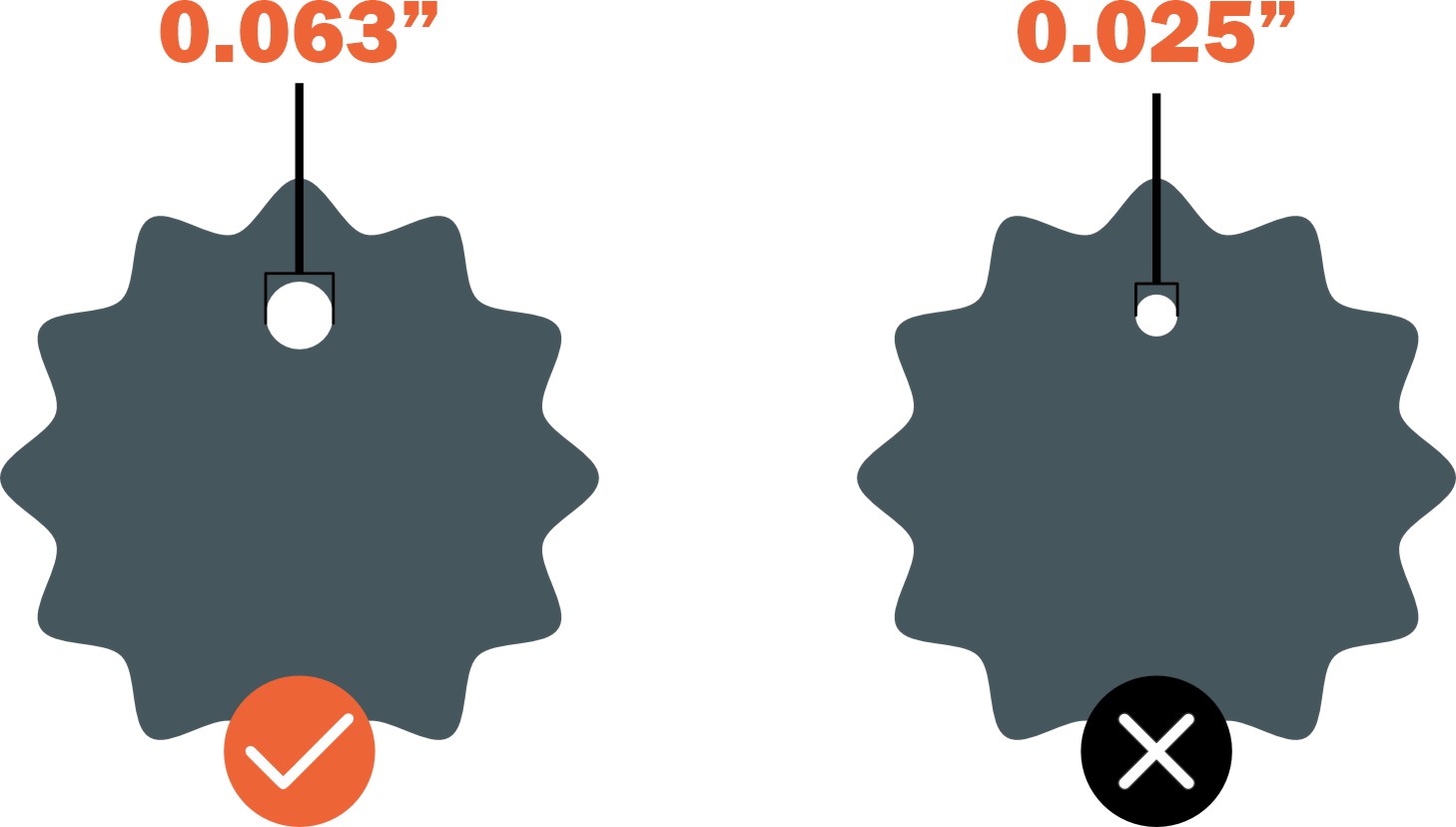

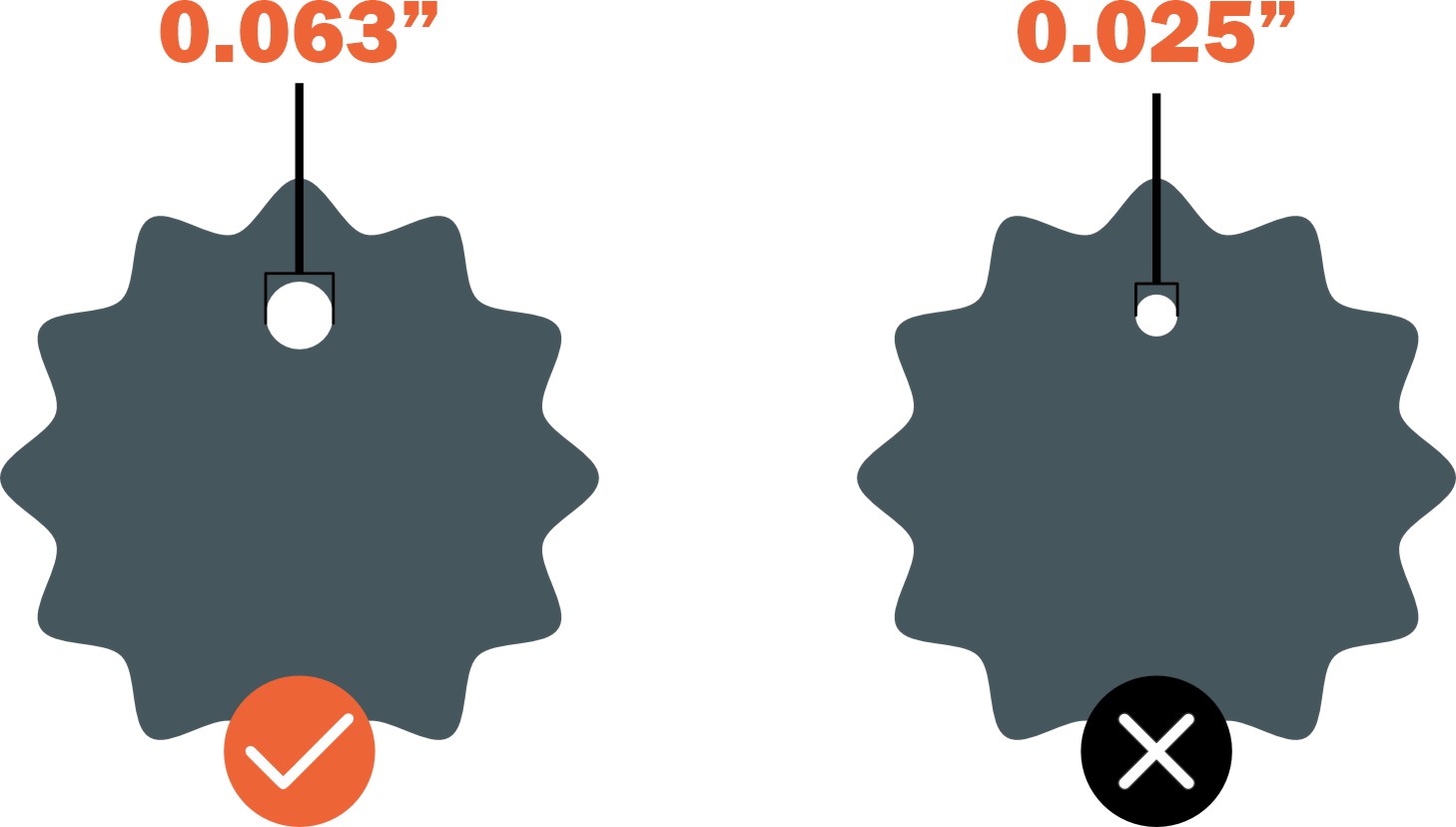

- Cutouts for hanging must be at least 0.063” in diameter

- No holes or cutouts smaller than 0.040”

- Powder coating adds 0.002" to 0.005” per side

All powder-coated parts must be at least 1″ x 3″. The shortest dimension should be no smaller than 1″, and the total area of the part should be no less than 3 square inches

Find the limits for all materials and post-processing services here: Processing Minimum and Maximum Flat Part Sizes

Each powder-coated part should have a hole or cutout of at least 0.063” (1.60mm) for hanging. Design holes or cutouts should not be smaller than 0.040” (1.02mm), as holes smaller than this may fill with powder during the coating process

We cannot plug tapped holes prior to powder coating, so any holes we tap for you will need to be chased with a tap to remove any powder buildup between the threads.

Parts will be sandblasted before powder coating to ensure a successful finish.

Powder coating adds between 0.004” (0.102mm) and 0.010” (0.254mm) to the overall thickness of your final part. Be sure to account for this in any areas of your design with small holes or tight clearances

Currently, we do not offer tab removal on powder-coated parts, so micro joints/tabs will be visible through the powder coat. They are typically 0.015-0.030″ in width, depending on the material, and roughly 0.010″ in height.

In addition, we cannot provide etching on any powder-coated parts as the powder will completely cover the etching.

All powder coat colors, except for the wrinkle black finish, will show fingerprints.

Pre-flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- Ensure all holes and cutouts are at least 50% of the material thickness for laser cut parts

- Ensure all holes and cutouts are at least 0.070” for most waterjet cut parts

- For all CNC routed parts, holes and cutouts must be at least 0.125”

- Create your file at a 1:1 scale, preferably using inch or millimeter units

- Ensure all objects are placed on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure no shapes have open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) includes bridges or is stencilized

- Ensure cut-out text (reversed text) includes bridges or is stencilized

Materials Available for Powder Coating

Validate your login