PRICING AND ORDER INFORMATION

Hardware insertion incurs a minimum additional charge of $9 to your cart total,

with per-hole pricing varying based on the selected fastener and quantity.

When placing your order, please note that hardware installation will add 1-3 business days to our standard processing times.

For further details, visit our Lead Times page.

GENERAL GEOMETRY REQUIREMENTS

All parts requiring hardware installation must meet specific size requirements to ensure proper manufacturing:

-

Min Part Size: 1” x 1.5”

-

Max Part Size: 36” x 46”

These are the general size requirements for hardware insertion. Please refer to the hardware catalog for specific details on

each type of hardware listed below to ensure your parts meet all specifications before submitting your order.

Holes up to 0.500″ can be selected for hardware installation. During the design process,

we will automatically resize the selected holes to match the required size based on the chosen hardware.

Please ensure you have adequate clearance to other features and edges of the material,

as the holes will be resized accordingly.

When combining hardware installation and bending, the minimum distance from the hole center to the bend line center varies depending on

the material. Please refer to our material catalog for specific details.

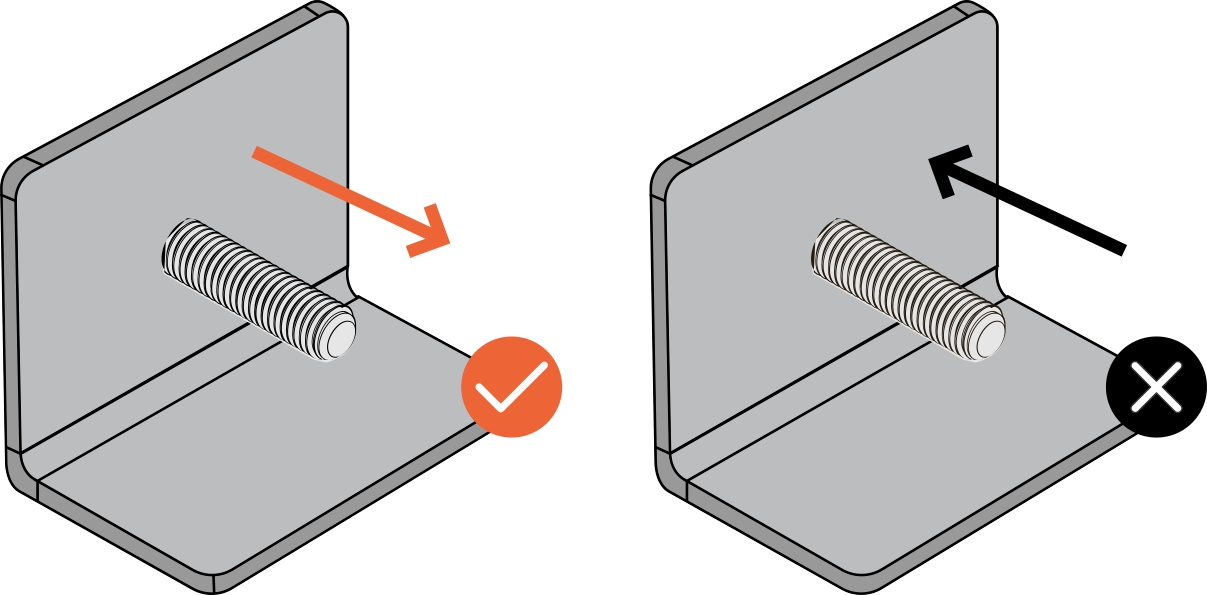

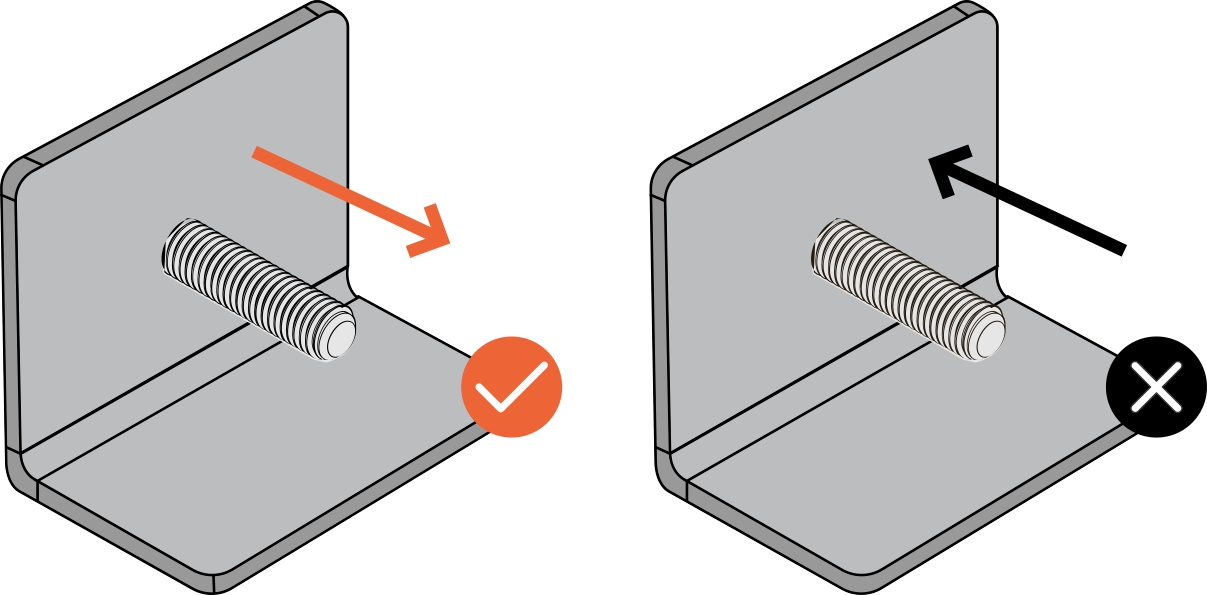

Hardware cannot be installed on parts with acute bends.

Hardware installation is not permitted on parts with acute bends. For any questions,

please contact our support team.

HARDWARE OPTIONS

Press Fit Nuts

Press fit nuts feature an internally threaded design with a knurled outer diameter. They are lightweight, simple to install, and can withstand high pressure and torque. These qualities make them ideal for flooring and aircraft applications

Press fit nuts offer load-bearing threads in metal sheets that are too thin to be tapped.

HARDWARE CATALOG

Press Fit Standoffs

Press fit or self-clinching standoffs are used to separate parts within an assembly and have a wide range of applications. They offer secure fastening for delicate components, with electrical parts being the most common use case. These standoffs provide a threaded fastener that ensures uniform spacing between parts.

HARDWARE CATALOG

Self-Clinching Studs

Also referred to as press fit studs, self-clinching studs are designed to serve as permanent fasteners in your assembly. Engineered to withstand high torque, stress, and heavy loads, these studs enhance the strength and durability of your parts across various applications.

Studs are typically employed when accessing one side of a threaded joint is inconvenient or impossible, or when there isn't enough clearance around the joint to use a traditional nut and bolt on the material surface.

HARDWARE CATALOG

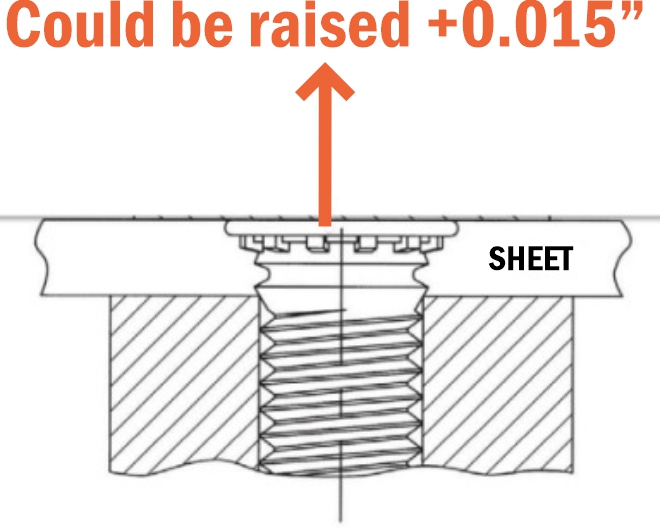

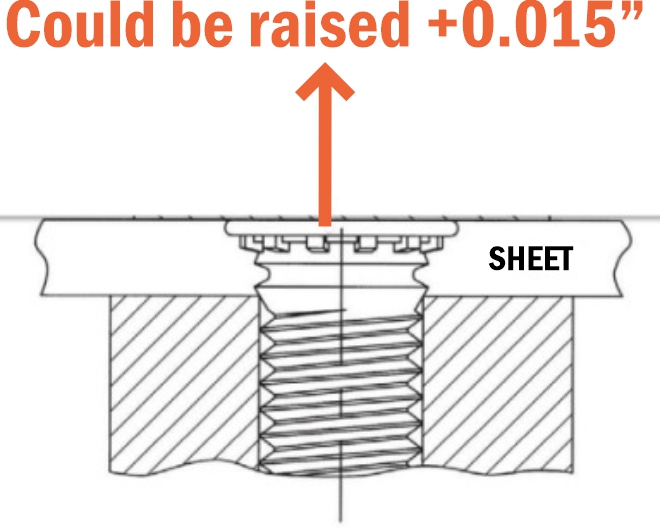

Flush Head Standoffs and Studs

Although our standoffs and studs are designed to be flush, they may be raised by up to .015″ depending on your material selection.

ADDING HARDWARE INSTALLATION TO YOUR ORDER

After confirming that your part meets our geometry requirements and uploading the file to our app, follow the normal order process and select “Add Hole Operations.

You will see a list of hole options where you can add hardware, along with a link to our catalog of hardware options. Choose your desired hardware and size, and it will appear on the 3D preview of your part. Ensure the hardware is placed on the correct face (top or bottom). Click "Add to Cart," and the hardware will be included in your order.

WHAT TO EXPECT

- Visible tool marks

- Be aware of potential scratching and marking on anodized or plated parts

- Hardware should only be used for its designated purpose

- Otherwise, shearing, splitting, or warping may occur.

- Improper use of hardware can lead to failure.

- For details on design requirements, visit the hardware catalog

- Hardware is installed after anodizing and plating processes are complete.

- Hardware installation occurs before powder coating

- Parts that are powder coated will have their hardware capped or plugged

Pre-Flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- All holes and cutouts are at least 50% of the material's thickness for laser cut parts

- All holes and cutouts are at least 0.070” for most waterjet cut parts

- All holes and cutouts are at least 0.125” for all CNC routed parts

- Ensure the file is created at a 1:1 scale, preferably in inch or millimeter units

- Ensure all objects are on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure all shapes are fully enclosed with no open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) has bridges or has been stencilized

Materials Available for Hardware

Validate your login