PRICING/ORDER INFO

Zinc Plating Adds a $19 minimum to your order, with quantity discounts starting when you order more than one identical part.

Nickel Plating Requires a custom quote and has a $200 batch minimum.

We pride ourselves on fast processing and shipping times, with standard orders shipping within 2-4 business days. Please note that plating will add 7-10 business days to the lead time. Plan accordingly when deciding when to place your order.

For the fastest delivery, we recommend placing a separate order for any parts that require plating. This way, we can process and ship the non-plated parts while the plated parts are being processed.

PLATING OPTIONS

Plating provides long-term protection against corrosion and wear. We select metals known for their rust and corrosion resistance to plate your parts.

Zinc is highly rust-resistant and can slow the corrosion rate of some materials by up to 30 years. It increases the life expectancy of the metal it coats due to its resistance to extreme temperatures.

Currently, we offer chloride rack zinc electroplating in three different finishes

Black – ASTM-B633 Type II SC2

Yellow – ASTM-B633 Type II SC2

Clear – ASTM-B633 Type III SC2

Nickel plating has a wide range of applications and offers excellent wear and corrosion resistance. When applied to copper, it maintains conductivity while benefiting from an increased operating temperature range.

Whether used for a clean final look or as an undercoating for further finishing, nickel plating can protect your parts and enhance their aesthetic appearance.

We provide bright electrolytic nickel plating in the following finish:

Clear – SAE-AMS-QQ-N-290 Grade G

GEOMETRY REQUIREMENTS

As with our other post-processing operations, parts must meet certain requirements to

achieve a successful plated finish.

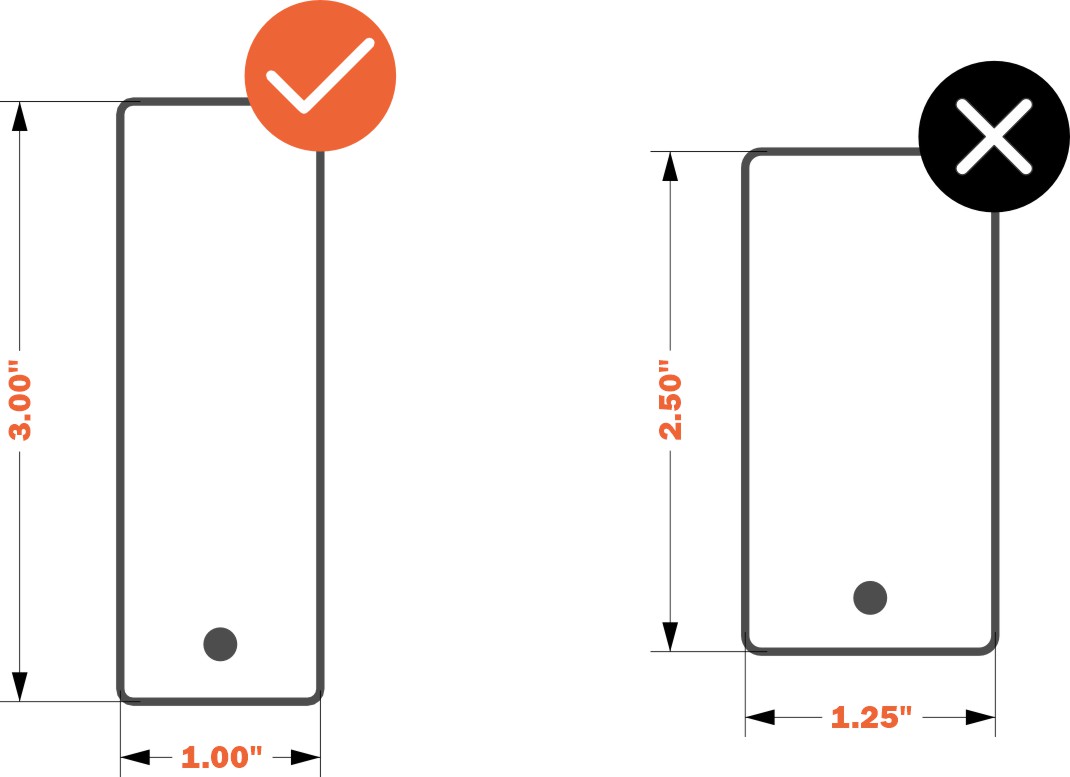

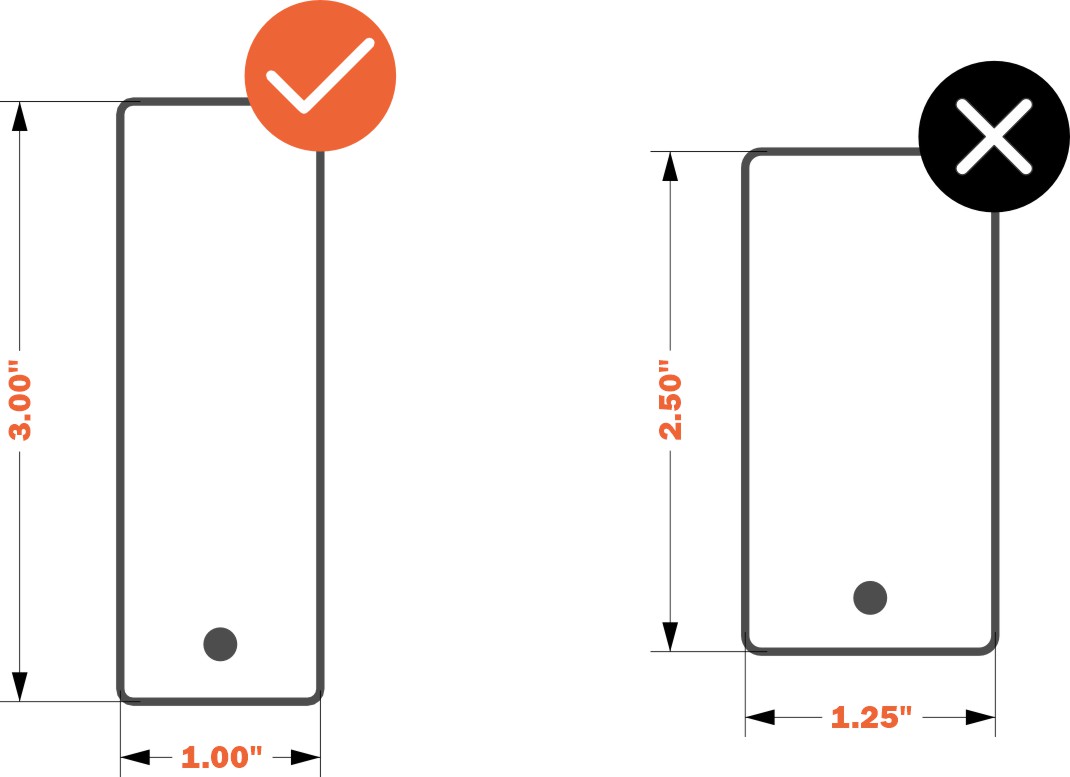

All plated parts must be at least 1″ x 3″ for processing. The shortest dimension should be no smaller than 1″, and the total area of the part should be no less than 3 square inches.

Plated parts can have a maximum size of 23” x 23”

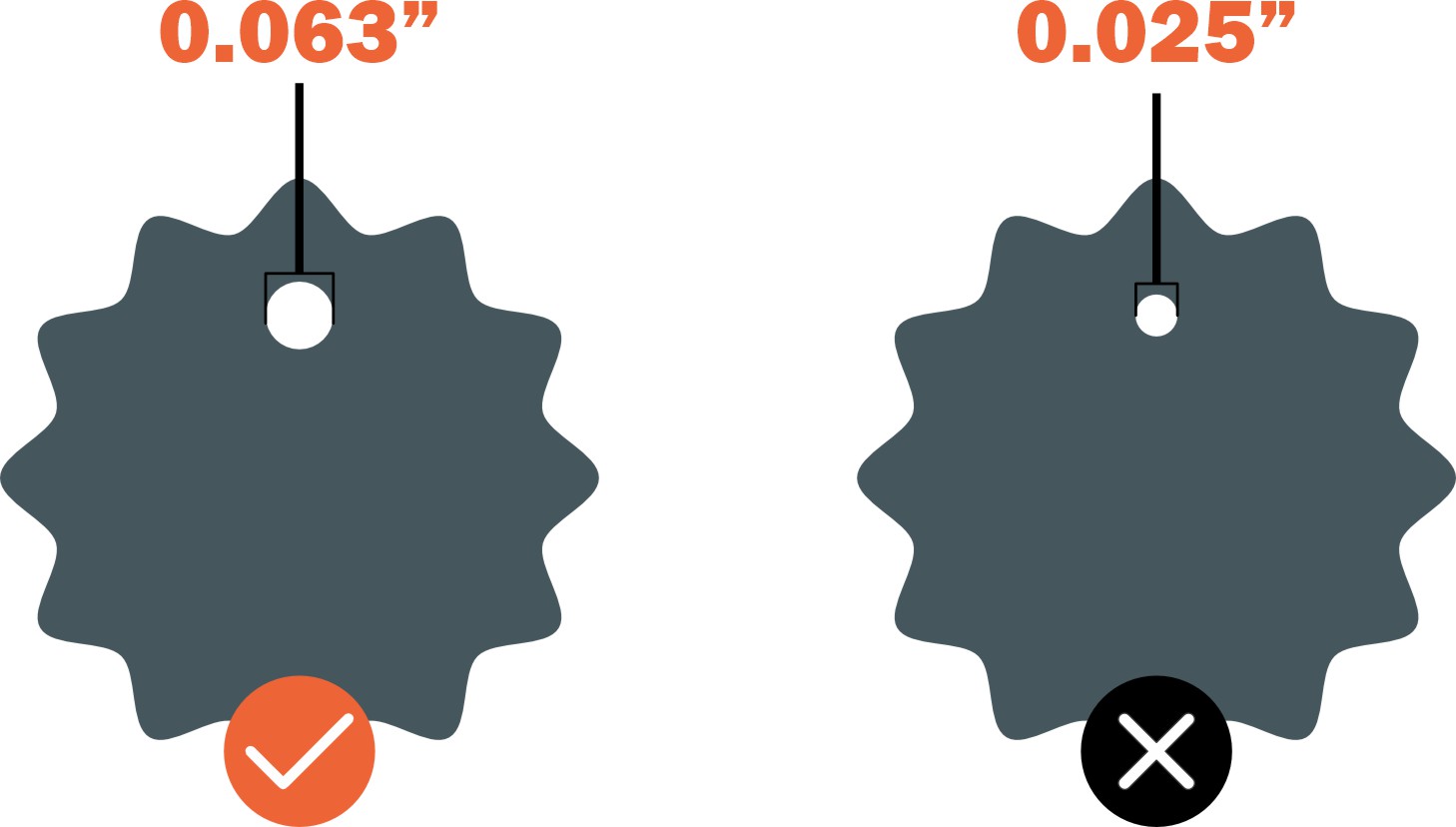

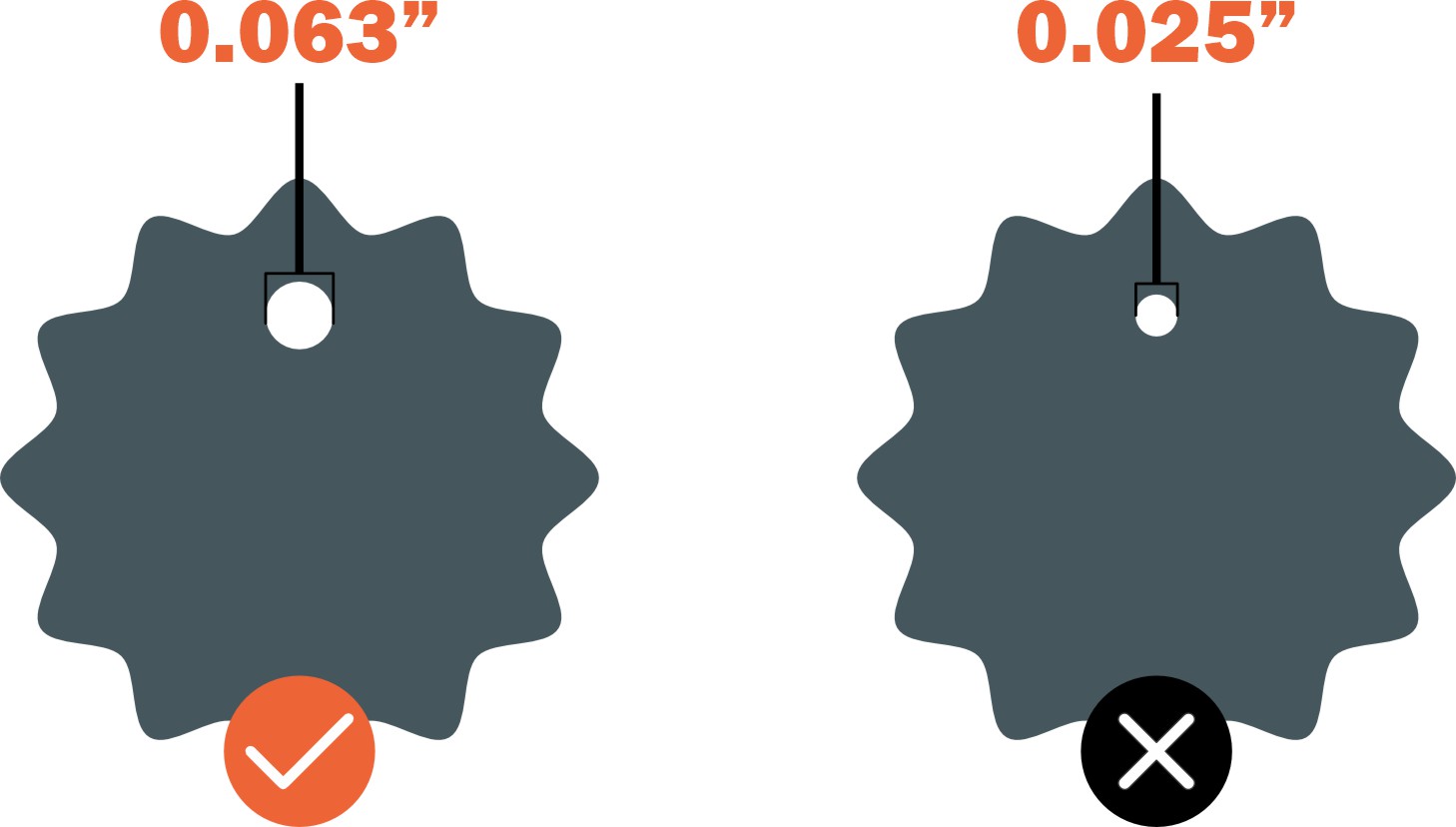

Additionally, your part must include a hole for hanging during plating. This hole must be at least 0.063” (1.6mm) or match the minimum hole size for your chosen material and thickness.

For example, if your part is 0.250” (6.35mm) thick Chromoly, the hole for plating must be at least 0.100” (2.54mm), as that is the minimum hole size allowed for 0.250” Chromoly.

The minimum hole size can be found in the Design Considerations section on each material page.

WHAT TO EXPECT

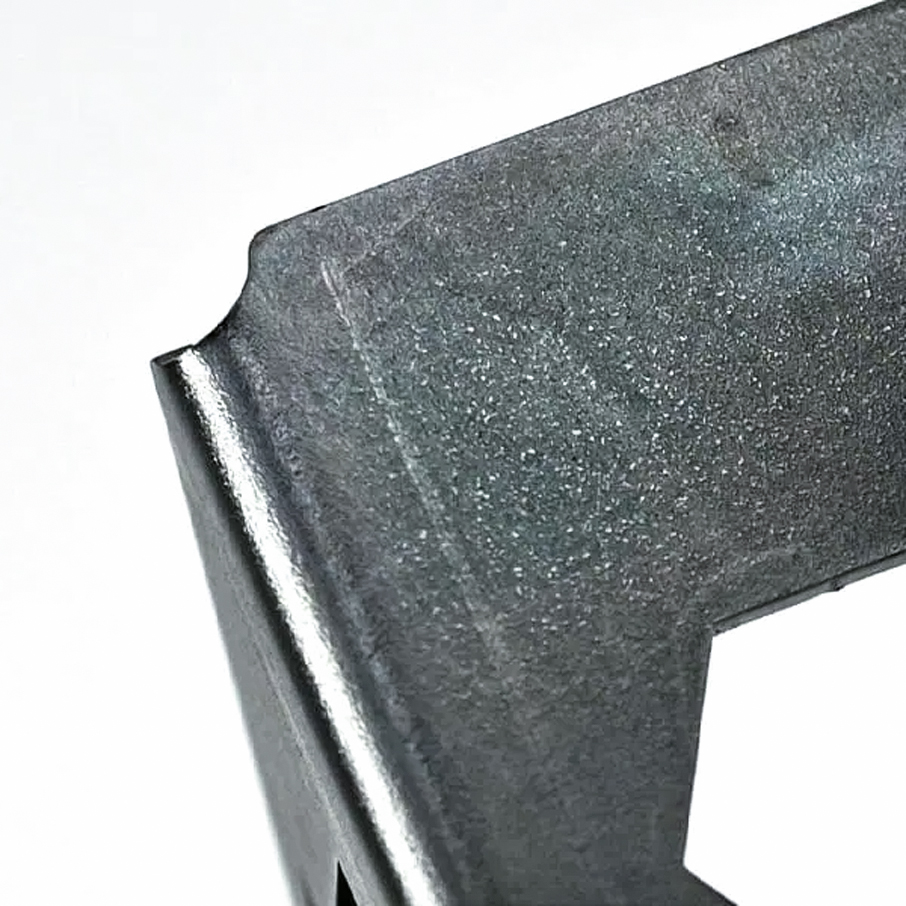

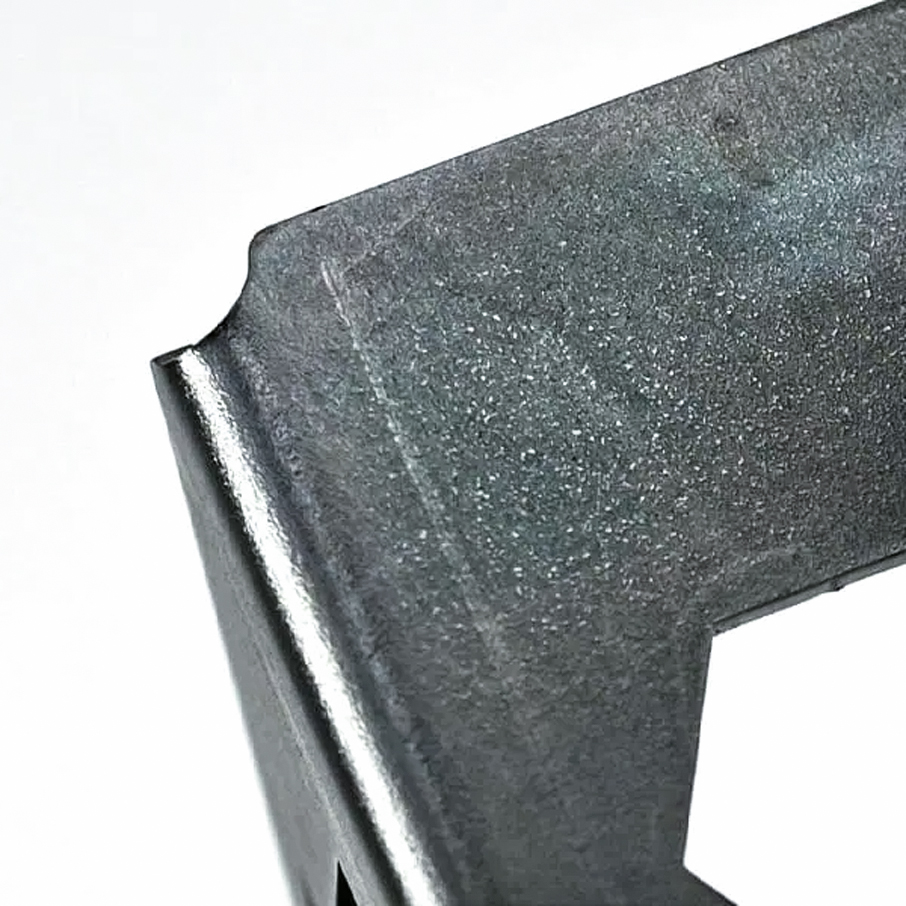

- Certain imperfections may be visible through the plating

- Colors and finishes may vary between batches

- Different alloys will produce varying color results

- Machining tabs may be visible through the plating and will need to be removed upon receiving the parts

- Currently, we do not provide de-tabbing services

- Aggressive use can scratch the plating, exposing the bare material underneath

- Bend lines will be visible through the plating, as die protection is unavailable

- Nickel plating generally adds 0.0002″ per side to the surface of your parts

- Zinc plating typically adds 0.0003″ per side to the surface of your parts

THINGS TO CONSIDER

- Any processing done after plating, such as hand-bending, grinding, or assembly,

can mark and affect the plating - Plating must be removed if you intend to weld your plated parts

Pre-Flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- All holes and cutouts are at least 50% of the material's thickness for laser cut parts

- All holes and cutouts are at least 0.070” for most waterjet cut parts

- All holes and cutouts are at least 0.125” for all CNC routed parts

- Ensure the file is created at a 1:1 scale, preferably in inch or millimeter units

- Ensure all objects are on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure all shapes are fully enclosed with no open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) has bridges or has been stencilized

Materials Available for Plating

Validate your login