ENHANCED DURABILITY AVAILABLE IN A VARIETY OF COLORS.

Black

Blue

Golden

Grey

Red

GEOMETRY REQUIREMENTS

Parts must meet specific requirements to be anodized successfully

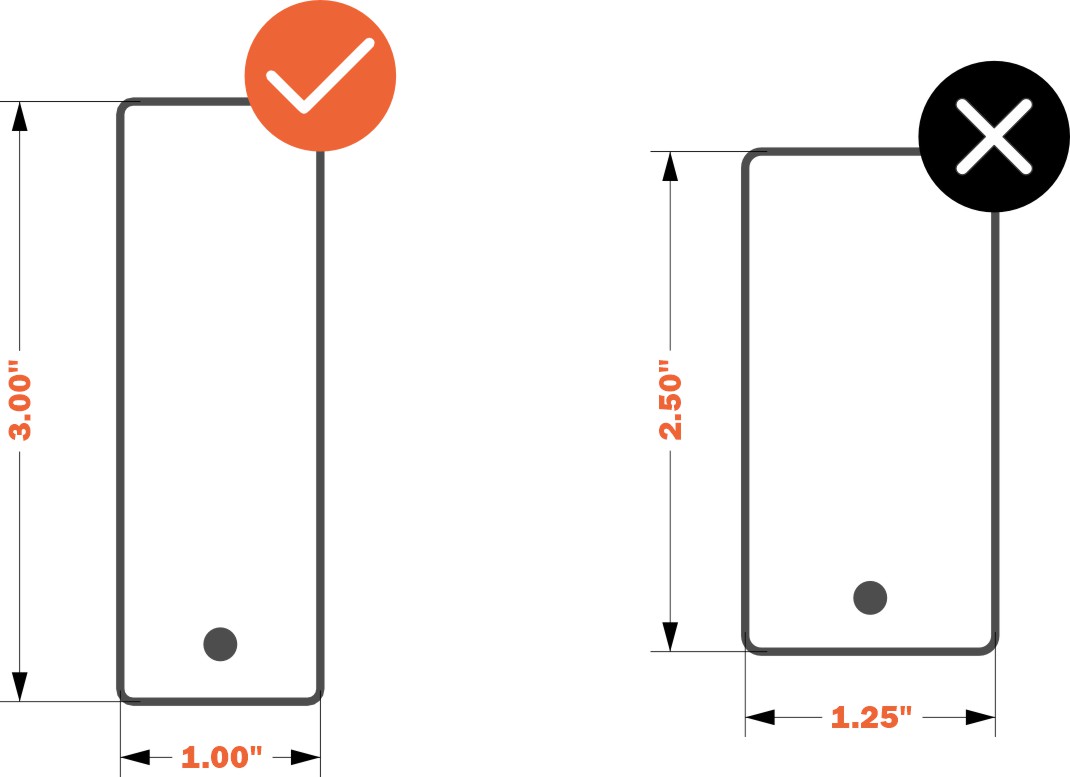

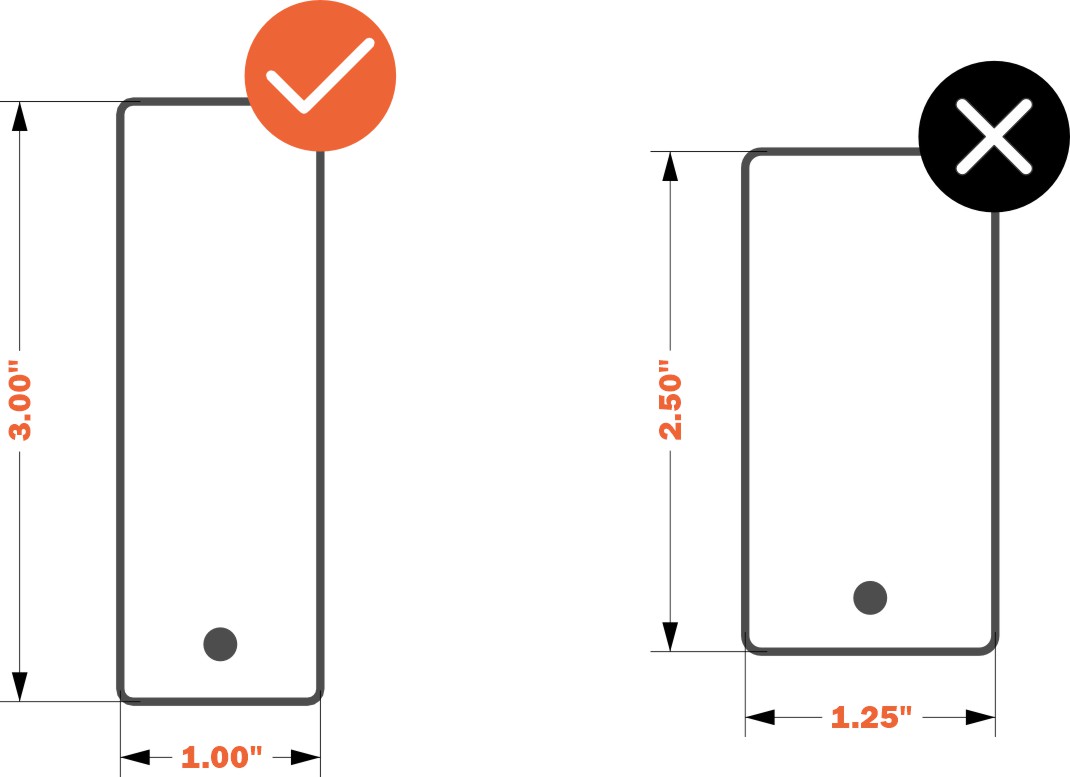

To meet handling and deburring needs, all anodized parts must be at least 1″ x 3″. The shortest dimension should be no smaller than 1″, and the total square area of the part should be at least 3″

Anodized parts can be a maximum of 23” x 23”. While anodizing sets the maximum size, your parts must also meet the deburring geometry requirements. Deburring will be a preselected option for all anodized parts

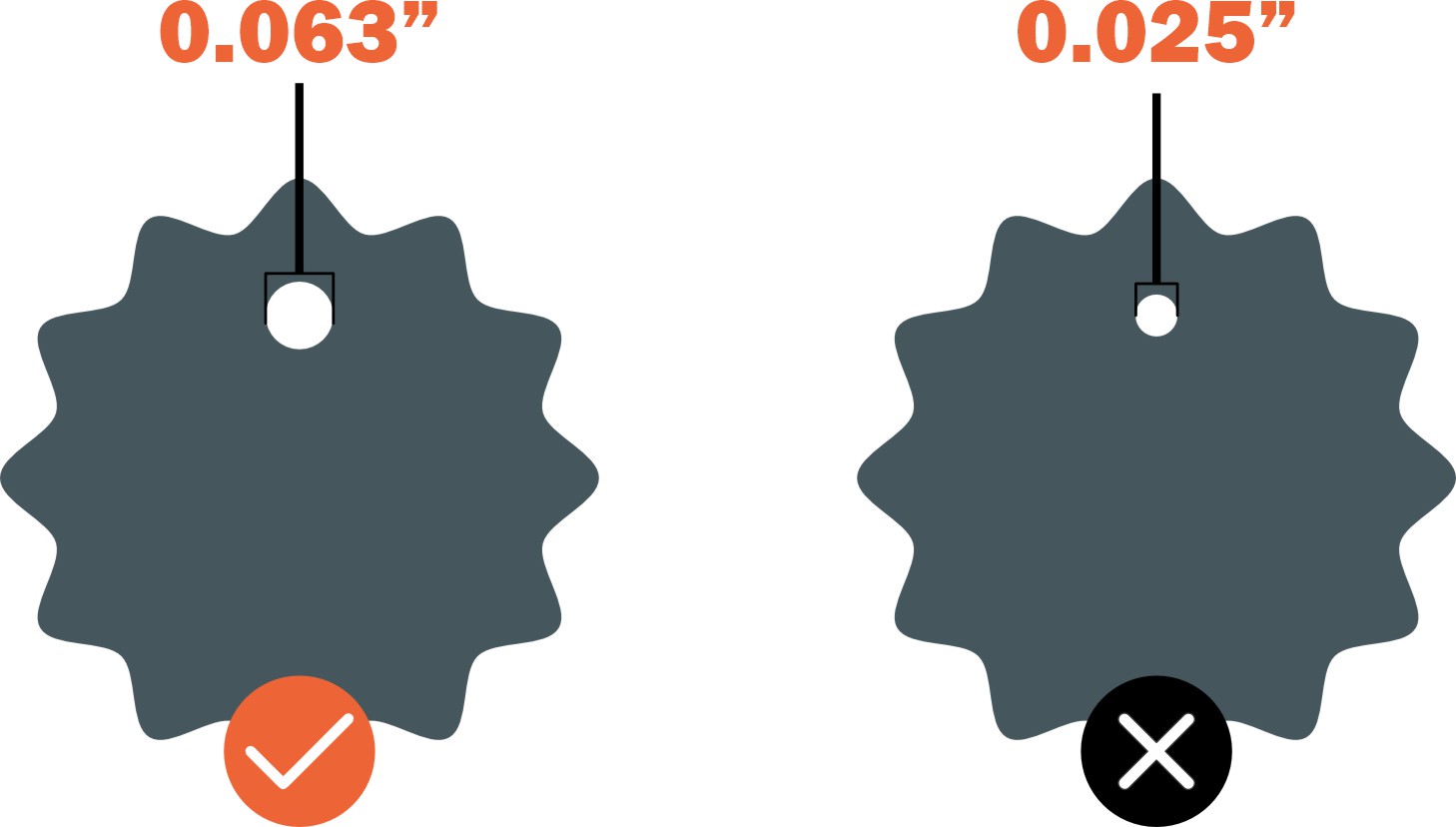

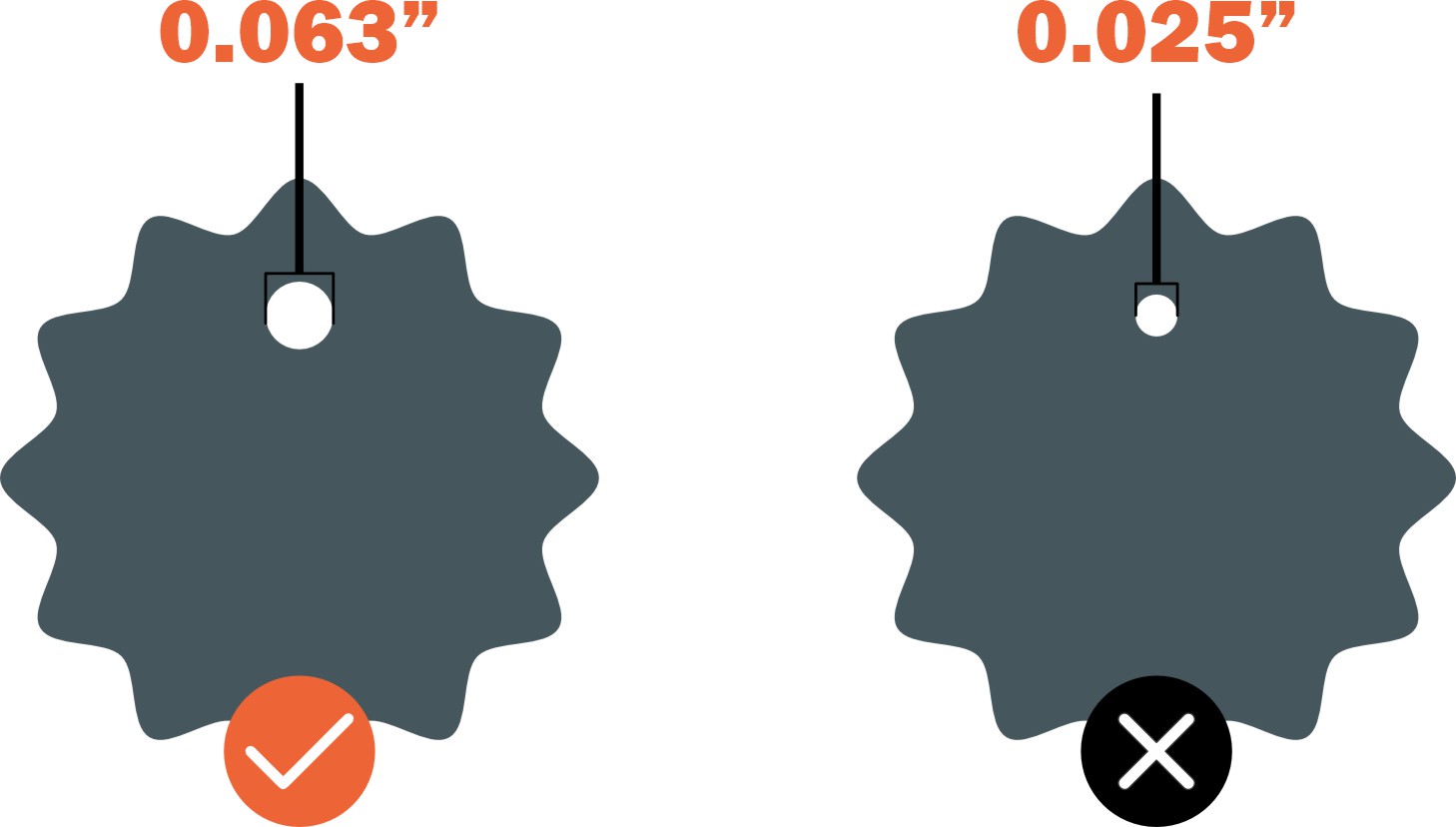

All anodized parts must include a hole for processing. The hole must be at least 0.063” (1.60mm). However, if the minimum hole size for your chosen material and thickness is larger than 0.063” (1.60mm), the hole should match that size instead

WHAT TO EXPECT

- Some imperfections may remain visible after anodizing

- Color finishes might vary between batches

- Different alloys will produce significantly different color finishes

- Anodized 7075 aluminum parts will exhibit duller coloring and a more noticeable

difference in appearance between the face and cut edge due to the material's high zinc content - If deburring is omitted, all imperfections will be visible and appear more severe

- We strongly recommend using our deburring service in conjunction with anodizing

- Parts that require welding should not be anodized

- Anodizing is a non-conductive process

- Anodized surfaces can scratch, revealing the raw material beneath

- Bend lines will be visible through the anodizing, as die protection is not available

- Type II anodizing will add approximately 0.0002” to 0.0009” per side to the surface of your parts

Pre-Flight Checklist

- Ensure your file is in an accepted format (2D: .dxf, .dwg, .ai, .eps; 3D: .step, .stp)

- All holes and cutouts are at least 50% of the material's thickness for laser cut parts

- All holes and cutouts are at least 0.070” for most waterjet cut parts

- All holes and cutouts are at least 0.125” for all CNC routed parts

- Ensure the file is created at a 1:1 scale, preferably in inch or millimeter units

- Ensure all objects are on the same layer

- Remove all stray points, duplicate lines, empty objects, and text areas

- Ensure all shapes are fully enclosed with no open contours

- Ensure all shapes are united, combined, or merged

- Convert all text to outlines or paths

- Ensure cut-out text (reversed text) has bridges or has been stencilized

Materials Available for Anodizing

Validate your login